Ikettle yeZinc

Incazelo Yomkhiqizo

Ithangi lokuncibilikisa i-zinc lokucwilisa izakhiwo zensimbi ngokushisa, ngokuvamile elibizwa ngokuthi ibhodwe le-zinc, lihlanganiswa kakhulu ngamapuleti ensimbi. Ibhodwe le-zinc lensimbi alilula nje kuphela ukulenza, kodwa futhi lifanelekela ukufudumeza ngemithombo ehlukahlukene yokushisa, futhi kulula ukulisebenzisa nokuyinakekela, lifanelekela kakhulu ukusekela ukusetshenziswa komugqa omkhulu wokukhiqiza i-hot-dip galvanizing yesakhiwo sensimbi.

Ikhwalithi yokugqoka okufakwe i-hot-dip galvanized kanye nokusebenza kahle kokukhiqiza kuhlobene kakhulu nobuchwepheshe benqubo esetshenziswayo kanye nokuphila kwesikhathi sebhodwe le-zinc. Uma ibhodwe le-zinc ligqwala ngokushesha kakhulu, kuzoholela ekulimaleni kwangaphambi kwesikhathi noma ngisho nokuvuza kwe-zinc ngokubhoboza. Ukulahlekelwa okuqondile kwezomnotho kanye nokulahlekelwa okuqondile kwezomnotho okubangelwa ukumiswa kokukhiqiza kukhulu.

Ukungcola okuningi kanye nezinto ezixubayo kuzokwandisa ukugqwala kwensimbi ebhavini le-zinc. Indlela yokugqwala kwensimbi ebhavini le-zinc ihluke ngokuphelele kwensimbi emkhathini noma emanzini. Ezinye izinsimbi ezinokumelana okuhle nokugqwala kanye nokumelana nokushiswa kwe-oxidation, njengensimbi engagqwali kanye nensimbi engashisi, zinokumelana okuphansi kokugqwala ne-zinc encibilikisiwe kunensimbi ye-silicon encibilikisiwe ephansi enokuhlanzeka okuphezulu. Ngakho-ke, insimbi ye-silicon encibilikisiwe ephansi enokuhlanzeka okuphezulu ivame ukusetshenziselwa ukwenza izimbiza ze-zinc. Ukwengeza inani elincane le-carbon kanye ne-manganese () ensimbini akunawo umthelela omkhulu ekumelaneni nokugqwala kwensimbi encibilikisiwe ne-zinc encibilikisiwe, kodwa kungathuthukisa amandla ensimbi.

Ukusetshenziswa kwe-zinc pot

- 1. Ukugcinwa kwembiza ye-zinc

Ubuso bembiza ye-zinc egqwalile noma egqwalile buzoba buqinile, okuzobangela ukugqwala okukhulu kwe-zinc ewuketshezi. Ngakho-ke, uma imbiza entsha ye-zinc idinga ukugcinwa isikhathi eside ngaphambi kokusetshenziswa, kufanele kuthathwe izinyathelo zokuvikela ukugqwala, okuhlanganisa ukuvikela ukupenda, ukuyibeka endaweni yokusebenzela noma yokumboza ukuze kugwenywe imvula, ukumboza phansi ukuze kugwenywe ukucwiliswa emanzini, njll. Akufanele nanini umhwamuko wamanzi noma amanzi aqongelelane embiza ye-zinc.

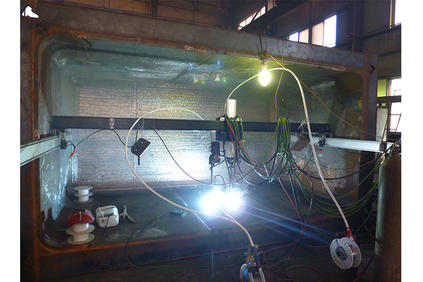

2. Ukufakwa kwebhodwe le-zinc

Uma ufaka ibhodwe le-zinc, kumele lithuthelwe esithandweni se-zinc ngokwezidingo zomenzi. Ngaphambi kokusebenzisa ibhodwe elisha, qiniseka ukuthi ususa ukugqwala, i-residual welding slag spatter kanye nokunye ukungcola kanye nokugqwala odongeni lwebhodwe. Ukugqwala kufanele kususwe ngendlela yemishini, kodwa ubuso bebhodwe le-zinc akufanele bonakaliswe noma bube bukhali. Ibhulashi le-fibre yokwenziwa eqinile lingasetshenziswa ekuhlanzeni.

Imbiza ye-zinc izokhula uma ishiswa, ngakho-ke kufanele kube nendawo yokukhula ngokukhululekile. Ngaphezu kwalokho, uma imbiza ye-zinc isesimeni sokushisa esiphezulu isikhathi eside, kuzokwenzeka "ukuhuzuka". Ngakho-ke, isakhiwo esifanele sokusekela kufanele sisetshenziswe embiza ye-zinc ngesikhathi sokuklama ukuze ivimbele ukuthi ingaguquguquki kancane kancane ngesikhathi sokusetshenziswa.