Isitshalo sokugaya insimbi esijika ukhiye sisebenza ngezinhlelo ezintathu eziyinhloko. Lezi zinhlelo zisebenza ukuze zilungiselele, zimboze futhi ziqede insimbi. Le nqubo isebenzisa amathuluzi akhethekile afanaImishini Yokubumba Izingxenye ZesakhiwofuthiIzingxenye Ezincane Imigqa Yokubumba (Robort)Imakethe yokukhiqiza amagesi ecwiliswe kakhulu ikhombisa amandla okukhula abalulekile.

| Ingxenye Yemakethe | Unyaka | Usayizi Wemakethe (USD Billion) | Unyaka Ocatshangelwayo | Usayizi Wemakethe Ocatshangelwayo (USD Billion) |

|---|---|---|---|---|

| I-Galvanizing Ecwiliswe Ngokushisayo | 2024 | 88.6 | 2034 | 155.7 |

Izinto Ezibalulekile Okufanele Uzicabangele

- Isitshalo sokugaya insimbi sinezinhlelo ezintathu eziyinhloko: ukuhlanza ngaphambi kokwelashwa, ukugaya insimbi, kanye nokuhlanza ngemva kokwelashwa. Lezi zinhlelo zisebenza ndawonye ukuhlanza, ukumboza, kanye nokuqeda insimbi.

- Uhlelo lwangaphambi kokwelashwa luhlanza insimbi. Lususa ukungcola, amafutha kanye nokugqwala. Lesi sinyathelo sisiza i-zinc ukuthi inamathele kahle ensimbini.

- Iuhlelo lokugayakubeka i-zinc coating ensimbini. Uhlelo lwangemva kokwelashwa luyapholisa insimbi futhi lunezela ungqimba lokugcina lokuvikela. Lokhu kwenza insimbi iqine futhi iqine.

Uhlelo 1: Uhlelo Lwangaphambi Kokwelashwa

Uhlelo Lokwelashwa Ngaphambi Kokwelashwa luyisigaba sokuqala nesibaluleke kakhuluinqubo yokufaka i-galvanizingUmsebenzi wayo oyinhloko ukulungisa indawo yensimbi ehlanzekile ngokuphelele. Indawo ehlanzekile ivumela i-zinc ukuthi yakhe isibopho esiqinile nesifanayo nensimbi. Lolu hlelo lusebenzisa uchungechunge lokucwilisa kwamakhemikhali ukususa konke ukungcola.

Amathangi Okususa Amafutha

Ukususa amafutha kuyisinyathelo sokuqala sokuhlanza. Izingxenye zensimbi zifika esitshalweni ezinokungcola okuphezulu njengowoyela, ukungcola, namafutha. Amathangi okususa amafutha asusa lezi zinto. Amathangi aqukethe izixazululo zamakhemikhali ezihlukanisa ukungcola. Izixazululo ezivamile zifaka:

- Izixazululo zokususa amafutha nge-alkaline

- Izixazululo zokususa amafutha nge-asidi

- Izihlanzi ze-alkaline ezishisa kakhulu

ENyakatho Melika, ama-galvanizer amaningi asebenzisa izixazululo ze-sodium hydroxide ezishisayo. Abasebenzi bavame ukushisa la matanki e-alkaline abe phakathi kuka-80-85 °C (176-185 °F). Lokhu kushisa kuthuthukisa ukusebenza kahle kokuhlanza ngaphandle kwezindleko zamandla aphezulu zokubilisa amanzi.

Amathangi Okuhlanza

Ngemva kokwelashwa ngamakhemikhali ngakunye, insimbi iya ethangini lokuhlanza. Ukuhlanza kuhlanza noma yimaphi amakhemikhali asele ethangini elidlule. Lesi sinyathelo sivimbela ukungcoliswa kokugeza okulandelayo ngokulandelana. Ukuhlanza okufanele kubalulekile ukuze kuqedwe kahle.

Izinga Lemboni:Ngokusho kwe-SSPC-SP 8 Pickling Standard, amanzi okugeza kumele ahlanzeke. Inani eliphelele lama-asidi noma usawoti oncibilikisiwe othuthwa uyiswa ematangini okugeza akufanele lidlule amagremu amabili ngelitha.

Amathangi Okuqoqwa Kwe-Acid

Okulandelayo, insimbi ifakwa ethangini lokugaya i-asidi. Leli thangi liqukethe isisombululo se-asidi esixutshiwe, ngokuvamile i-hydrochloric acid. Umsebenzi we-asidi ukususa ukugqwala kanye nesilinganiso sokugaya, okuyi-iron oxides ebusweni bensimbi. Inqubo yokugaya iveza insimbi engenalutho, ehlanzekile ngaphansi, okwenza ilungele isinyathelo sokugcina sokulungiselela.

Amathangi Okufudumeza

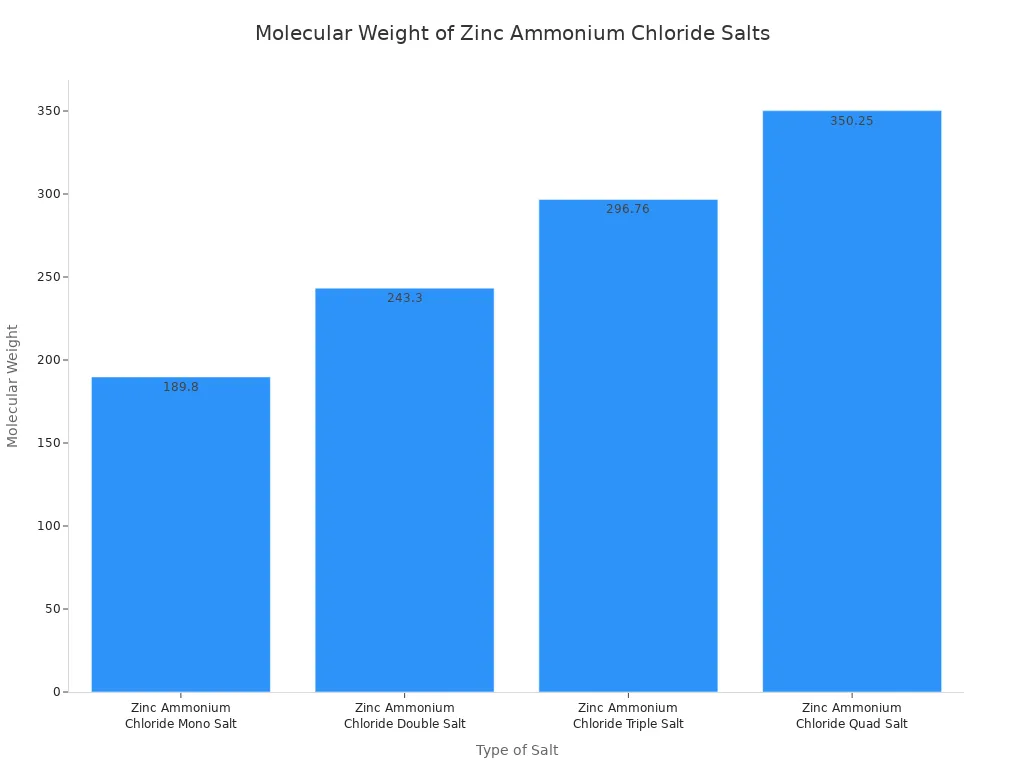

Ukuhlanza kuyisinyathelo sokugcina ngaphambi kokwelashwa. Insimbi ehlanzekile ingena ku-ithangi lokushintshashintshaequkethe isixazululo se-zinc ammonium chloride. Lesi sixazululo sisebenzisa ungqimba oluvikelayo lwekristalu ensimbini. Lesi ngqimba senza izinto ezimbili: senza ukuhlanza okuncane kokugcina futhi sivikele insimbi emoyeni. Le filimu evikelayo ivimbela ukugqwala okusha ukuthi kungabikho ngaphambi kokuba insimbi ingene eketheni elishisayo le-zinc.

Umthombo Wesithombe:statics.mylandingpages.co Uhlelo 2: Uhlelo Lokubumba I-Galvanizing

Ngemva kokwelashwa kwangaphambili, insimbi ithuthelwa ohlelweni lwe-Galvanizing. Inhloso yalolu hlelo ukusebenzisaisembozo se-zinc esivikelayoYakhiwe yizingxenye ezintathu eziyinhloko: ihhavini yokomisa, isithando sokushisa igesi, kanye nekettle ye-zinc. Lezi zingxenye zisebenza ndawonye ukudala isibopho sensimbi phakathi kwensimbi ne-zinc.

Ihhavini Yokomisa

Ihhavini yokomisa liyindawo yokuqala okufanele ibekwe kuyo kulolu hlelo. Umsebenzi walo oyinhloko ukomisa insimbi ngokuphelele ngemva kwesigaba sokugeleza. Abasebenzi bavame ukushisa ihhavini cishe ku-200°C (392°F). Lokhu kushisa okuphezulu kushabalalisa wonke umswakama osele. Inqubo yokomisa ephelele ibalulekile ngoba ivimbela ukuqhuma komusi ku-zinc eshisayo futhi igwema amaphutha okumboza njengemigodi yama-pin.

Ama-oven omile esimanje anemiklamo yokonga amandla. Lezi zici zinciphisa ukusetshenziswa kukaphethiloli futhi zithuthukisa ukusebenza kahle kwezitshalo.

- Bangasebenzisa amagesi okukhipha umoya avela esithandweni somlilo ukuze bafudumale insimbi kusengaphambili.

- Ngokuvamile zihlanganisa izinhlelo zokubuyisa ukushisa.

- Ziqinisekisa ukusatshalaliswa kokushisa okuhle nokulinganayo.

Isithando Somlilo Esihlanganisa I-Galvanizing

Isithando somlilo esisebenza ngogesi sinikeza ukushisa okukhulu okudingekayo ukuze kuncibilikiswe i-zinc. Lawa mayunithi anamandla azungeze i-zinc kettle futhi agcina i-zinc encibilikisiwe ekushiseni okunembile. Izithando zisebenzisa ubuchwepheshe obuhlukahlukene bokushisa obuthuthukisiwe ukuze zisebenze kahle. Izinhlobo ezivamile zifaka:

- Izishisi Ezishisa Ngesivinini Esiphezulu Eziqhumayo

- Izithando Zokushisa Ezingaqondile

- Izithando Zikagesi

Ukuphepha Kuqala: Izitofu zisebenza emazingeni okushisa aphezulu kakhulu, okwenza ukuphepha kubaluleke kakhulu. Zakhiwe nge-insulation yokushisa okuphezulu, izinzwa zedijithali zokuqapha izinga lokushisa kwekettle, kanye nemiklamo evumela ukuhlolwa okulula kwezishisi nama-valve okulawula.

Ikettle yeZinc

Ikettle ye-zinc iyisitsha esikhulu, esiyisikwele esiphethe i-zinc encibilikisiwe. Ihlala ngqo ngaphakathi kwesithando somlilo esikhanyisayo, esisifudumezayo. Ikettle kumele iqine kakhulu ukuze imelane namazinga okushisa aphezulu aqhubekayo kanye nesimo sokugqwala kwe-zinc ewuketshezi. Ngenxa yalesi sizathu, abakhiqizi bakha amakettle ngensimbi ekhethekile, enekhabhoni ephansi, ne-silicon ephansi. Amanye angase abe nolwelwesi lwangaphakathi lwesitini esingenakunyakaziswa ukuze aphile isikhathi eside.

Uhlelo 3: Uhlelo Lwangemva Kokwelashwa

Uhlelo Lwangemva Kokwelashwa luyisigaba sokugcina ku-inqubo yokufaka i-galvanizingInhloso yayo ukupholisa insimbi esanda kufakwa bese ifaka ungqimba lokugcina lokuvikela. Lolu hlelo luqinisekisa ukuthi umkhiqizo unokubukeka okufiselekayo kanye nokuqina kwesikhathi eside. Izingxenye eziyinhloko amathangi okucima kanye neziteshi zokudlulisa umoya.

Amathangi Okucima

Ngemva kokuphuma eketheni le-zinc, insimbi isashisa kakhulu, cishe ngo-450°C (840°F). Amathangi okucima ugesi ayapholisa insimbi ngokushesha. Lokhu kupholisa okusheshayo kuyayekisa ukusabela kwensimbi phakathi kwe-zinc nensimbi. Uma insimbi iphola kancane emoyeni, lokhu kusabela kungaqhubeka, kubangele ukuphela okufiphele, okunamabala. Ukucima ugesi kusiza ukugcina ukubukeka okukhanyayo nokufana kakhulu. Kodwa-ke, eminye imiklamo yensimbi ayifaneleki ukucima ugesi ngoba ukushintsha kwezinga lokushisa okusheshayo kungabangela ukugoba.

Abasebenzi basebenzisa uketshezi oluhlukile, noma izindlela zokuxhumana, ukuze bacime ngokusekelwe emphumeleni ofiselekayo:

- Amanzi:Inikeza ukupholisa okusheshayo kodwa ingakha usawoti we-zinc osuswayo phezu kwamanzi.

- Amafutha:Pholisa insimbi kancane kakhulu kunamanzi, okunciphisa ingozi yokuqhekeka ngenkathi kuthuthukiswa ukuguquguquka kwayo.

- Usawoti Oncibilikisiwe:Nikeza izinga lokupholisa elihamba kancane nelilawulwa kakhudlwana, okunciphisa ukuphambuka.

Ukudlula kanye Nokuqeda

Ukudlula kuyindlela yokugcina yokwelapha ngamakhemikhali. Le nqubo isebenzisa ungqimba oluncane, olungabonakali ebusweni obuhlanganisiwe. Lolu ungqimba luvikela uqweqwe olusha lwe-zinc ekungcolisweni ngaphambi kwesikhathi kanye nokwakheka “kokugqwala okumhlophe” ngesikhathi sokugcina nokuthutha.

Inothi Lokuphepha Nezemvelo:Ngokomlando, i-passivation yayivame ukusebenzisa izinto eziqukethe i-hexavalent chromium (Cr6). Kodwa-ke, leli khemikhali linobuthi futhi libanga umdlavuza. Izinhlangano zikahulumeni ezifana ne-US Occupational Safety and Health Administration (OSHA) zilawula ngokuqinile ukusetshenziswa kwalo. Ngenxa yalezi zinkinga zezempilo nezemvelo, imboni manje isebenzisa kabanzi ezinye izindlela eziphephile, njenge-trivalent chromium (Cr3+) kanye nama-passivator angenayo i-chromium.

Lesi sinyathelo sokugcina siqinisekisa ukuthiumkhiqizo we-galvanizedifika lapho iya khona ihlanzekile, ivikelekile, futhi ilungele ukusetshenziswa.

Izinhlelo Zokusekela Ezibalulekile Zomhlaba Wonke Zezitshalo

Izinhlelo ezintathu eziyinhloko esitshalweni sokugaya zithembele ezinhlelweni zokusekela ezibalulekile ukuze zisebenze ngokuphepha nangokusebenza kahle. Lezi zinhlelo zesitshalo sonke zisingatha ukunyakaza kwezinto, imisebenzi ekhethekile yokumboza, kanye nokuphepha kwemvelo. Zixhumanisa yonke inqubo kusukela ekuqaleni kuze kube sekupheleni.

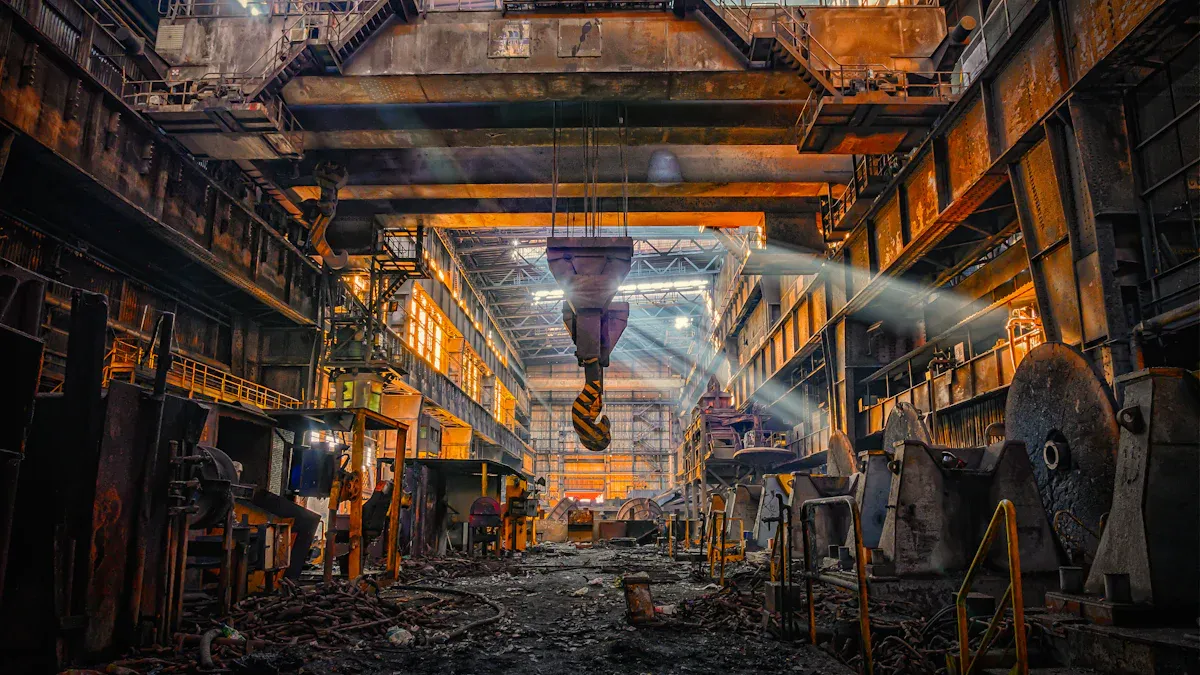

Uhlelo Lokuphatha Izinto

Uhlelo lokuphatha izinto luhambisa izinto ezisindayo ezenziwe ngensimbi kuyo yonke indawo. Izitshalo zesimanje zokugalela ngogesi zidinga ama-crane asezingeni eliphezulu kanye neminye imishini ukuphatha umsebenzi. Le mishini kumele iphathe isisindo sezinto futhi imelane nokushisa okuphezulu kanye nokuchayeka kumakhemikhali.

- Ama-crane

- Ama-hoist

- Ama-Conveyor

- Abaphakamisi

Abaqhubi kumele bacabangele umthamo omkhulu womthwalo walo mshini. Uma kwenziwa izinto ezisindayo kakhulu, kungcono ukubonisana ne-galvanizer ukuqinisekisa ukuthi uhlelo lwabo luyakwazi ukusingatha isisindo. Lokhu kuhlela kuvimbela ukubambezeleka futhi kuqinisekisa ukuphathwa okuphephile.

Imishini Yokubumba Izingxenye Zesakhiwo

Ukusetshenziswa kwezitshaloImishini Yokubumba Izingxenye Zesakhiwoukuze kufezwe ungqimba olufanayo lwe-zinc ezintweni ezinkulu noma eziyinkimbinkimbi. Ukucwilisa okujwayelekile kungase kunganeli izingcezu ezinezimo ezingajwayelekile noma izindawo zangaphakathi. Lo mshini okhethekile usebenzisa amasu athuthukile, njengokunyakaza kwezingxenye okulawulwayo noma izinhlelo zokufafaza ezenzakalelayo, ukuqinisekisa ukuthi i-zinc encibilikisiwe ifinyelela yonke indawo ngokulinganayo. Ukusebenzisa Imishini Yokugaya Izingxenye Efanele Yesakhiwo kubalulekile ekuhlangabezaneni nezindinganiso zekhwalithi ezintweni ezifana nemishayo emikhulu noma izinhlangano eziyinkimbinkimbi. Ukusetshenziswa okufanele kweMishini Yokugaya Izingxenye Yesakhiwo kuqinisekisa ukuphela okuqhubekayo nokuvikelayo.

Ukukhishwa Nokwelashwa Kwefutha

Inqubo yokufaka igesi idala umusi, ikakhulukazi ovela emathangini okuqoqa i-asidi kanyeikettle eshisayo ye-zincUhlelo lokukhipha nokwelapha intuthu lubalulekile ekuphepheni kwabasebenzi kanye nokuvikelwa kwemvelo. Lolu hlelo lubamba umusi oyingozi emthonjeni wawo, luhlanze umoya ngokusebenzisa izihlungi noma izihlungi, bese luwukhipha ngokuphephile.

Ukuphepha Nemvelo:Ukukhipha intuthu ngempumelelo kuvikela abasebenzi ekuhogeleni umusi wamakhemikhali futhi kuvimbela ukukhishwa kokungcola emoyeni, okuqinisekisa ukuthi isitshalo silandela imithethonqubo yezemvelo.

Isitshalo sokugaya esinokhiye ojikayo sihlanganisa izinhlelo ezintathu eziyinhloko. Ukuhlanza insimbi ngaphambi kokwelashwa kuhlanzwa ukuze kutholakale ukunamathela kwe-zinc. Uhlelo lokugaya lusebenzisa isembozo, futhi ngemva kokwelashwa luqeda umkhiqizo. Izinhlelo zokusekela, okuhlanganisa ne-Structural Component Galvanizing Equipment, zihlanganisa yonke inqubo. Izitshalo zanamuhla zisebenzisa okuzenzakalelayo kanye nezinkomba zokusebenza ezibalulekile ukuthuthukisa ukusebenza kahle kanye nokusimama.

Isikhathi sokuthunyelwe: Novemba-03-2025