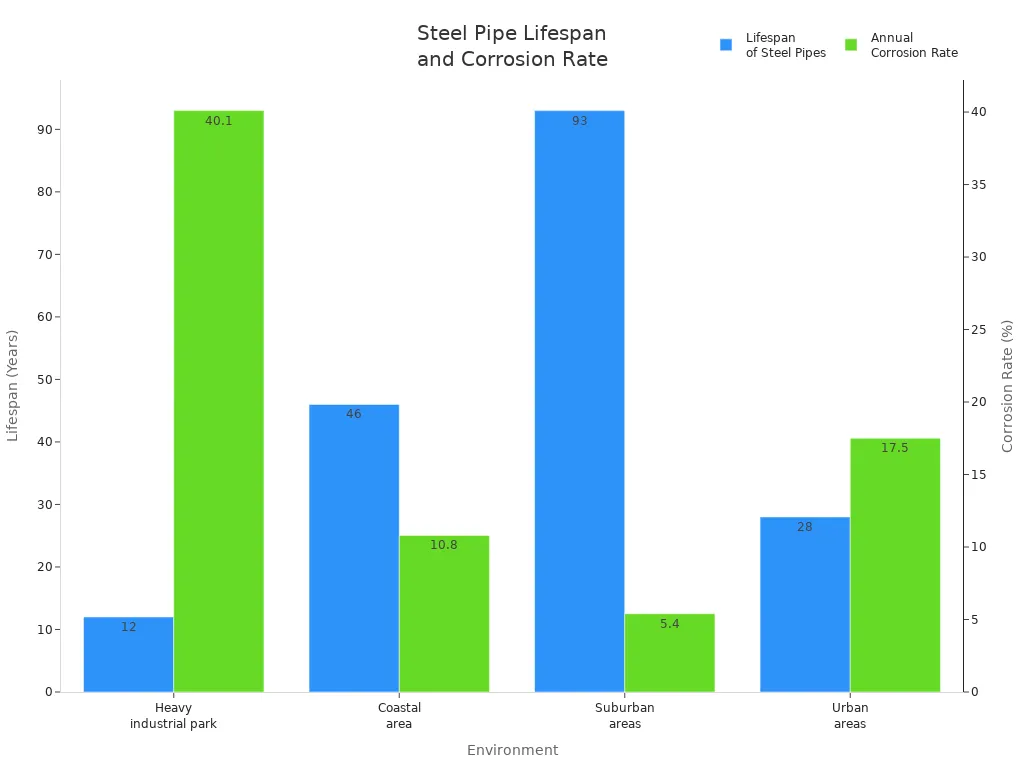

Uvikela amapayipi ensimbi ekugqwaleni ngokusebenzisa i-hot-dip galvanizing.Imishini yokugaya ipayipi lensimbi eshisayoimboza ipayipi ngalinye nge-zinc, okwenza isivikelo ekugqwaleni.Amapayipi Imigqa yokugayasiza ukuqinisekisa ukuthi ukuqeda kuqinile futhi kuyafana. Bheka ishadi elingezansi. Libonisa ukuthi amapayipi e-galvanized ahlala isikhathi eside kangakanani ezindaweni ezahlukene.

Izinto Ezibalulekile Okufanele Uzicabangele

- Ukushisa okushisayoivikela amapayipi ensimbi ekugqwaleni ngokusebenzisa i-zinc coating ejiyile, esebenza njengesivikelo ekugqwaleni.

- Ukulungiswa kahle kwendawoKubalulekile. Ukuhlanza nokukhuhla amapayipi kuqinisekisa ukuthi i-zinc inamathela kahle, okuvimbela amaphutha embozweni.

- Amapayipi e-galvanized ahlala isikhathi eside, avame ukuhlala iminyaka engama-40 kuya kwengama-50, okwenza abe ukukhetha okungabizi kakhulu kwezimboni ezahlukahlukene.

Imishini Yokucwilisa I-Hot-Dip Galvanizing kanye Nezinyathelo Zenqubo

Ipayipi lensimbiimishini yokugaya ngogesi eshisayokukusiza ukuvikela amapayipi ensimbi ekugqwaleni nasekulimaleni. Usebenzisa le mishini ezimbonini eziningi, njengokwakha, imishini, izitshalo zamakhemikhali, kanye nezitimela. Le mishini iphatha amapayipi anobubanzi obusukela ku-1/2 kuya ku-10 inches kanye nobude obusukela kumamitha angu-4 kuya kwangu-8. Ingamboza amapayipi nge-zinc enesisindo esiphakathi kwamagremu angu-50 no-400 ngemitha yesikwele. Le mishini ingacubungula amathani afinyelela ku-80,000 amapayipi ensimbi minyaka yonke.

| Into | Imininingwane |

|---|---|

| izinto | ucingo lwensimbi |

| ububanzi bobubanzi | 1/2 ~10 intshi |

| ububanzi bobude bepayipi | 4~8 m |

| uhlobo lokumboza | i-zinc |

| isisindo sokumboza | 50~400g/m2 |

| umthamo | 40000~80000T/ngonyaka |

Ukulungiswa Nokuhlanza Okungaphezulu

Uqala ngokuhlanza amapayipi ensimbi. Lesi sinyathelo sisusa ukungcola, uwoyela, nezinye izinto ezingcolisayo. Uma weqa ukuhlanza, i-zinc coating ngeke inamathele kahle. Udinga ukususa i-weld slag, ama-burrs, i-mill scale, ama-varnish, ama-epoxies, isihlabathi, upende olusekelwe ku-oyela, ama-crayon marks, kanye ne-wax noma i-grease ejiyile. Usebenzisa amabhati okususa amafutha nge-sodium hydroxide ukususa amafutha namafutha. Ngemva kokususa amafutha, uhlanza amapayipi ngamanzi. Ube ususebenzisa i-hydrochloric noma i-sulfuric acid ukususa ukugqwala kanye ne-mill scale. Lesi sinyathelo sibizwa ngokuthi i-pickling.

Icebiso: Hlanza njalo amapayipi ngemva kokuhlanza i-asidi ukuze ususe yonke iminonjana ye-asidi. Yomisa amapayipi ngokuphelele ngaphambi kokudlulela esinyathelweni esilandelayo.

Ukuhlanza Amapayipi Ensimbi

Okulandelayo, ucwilisa amapayipi ngesisombululo se-flux. I-Fluxing isusa noma yimaphi ama-oxide asele futhi ivimbele i-oxidation entsha ngaphambi kokuthi umboze amapayipi nge-zinc. Usebenzisa isisombululo se-zinc ammonium chloride kulesi sinyathelo. Izinga lokushisa elihle kakhulu loku-flux liphakathi kuka-60 no-80 °C. Leli zinga lokushisa lisiza i-flux ukuhlanza kahle ubuso bensimbi. Izinto eziyinhloko ezi-fluxing yi-zinc chloride kanye ne-ammonium chloride. Lawa makhemikhali asusa i-iron oxide futhi athuthukise ukugeleza kwe-zinc. I-Fluxing ikusiza futhi ukuthi usebenzise i-zinc encane futhi inciphise imfucuza.

- I-zinc chloride: 60–80%

- I-Ammonium chloride: 7–20%

- Izinto zokuguqula uketshezi: 2–20%

- Amanye ama-compounds: i-nickel, i-cobalt, i-manganese, i-lead, i-tin, i-bismuth, i-antimony

Ukucwiliswa ebhavini leZinc

Ube usucwilisa amapayipi ebhavini le-zinc encibilikisiwe. Imishini yokugaya i-hot-dip yepayipi lensimbi igcina ibhavini le-zinc lisekushiseni okulungile, ngokuvamile phakathi kuka-825 no-870 °F (440–460 °C). Ugcina amapayipi ebhavini imizuzu emi-5 kuya kweyi-15. Kulokhu uvumela i-zinc ukuthi ihlangane nensimbi futhi yakhe ungqimba oluqinile, olulinganayo. Ibhavini le-zinc limboza yonke ingxenye yepayipi, ngisho nangaphakathi nangaphandle kwama-weld.

Qaphela: Uma ungalawuli izinga lokushisa noma isikhathi, ungase uthole amaphutha afana nama-pimples, ama-blister, noma ukuxebuka.

Ukupholisa Nokuhlanza Kokugcina

Ngemva kokukhipha amapayipi ebhavini le-zinc, uwapholisa ethangini lokucima umlilo. Ukupholisa kuvimbela ukusabela phakathi kwe-zinc nomoya. Bese uhlanza amapayipi ngamanzi ahlanzekile ukuze ususe noma yimaphi amakhemikhali asele. Uma usebenzise ukuhlanza nge-asidi, hlanza amapayipi okwesibili. Yomisa amapayipi ngomoya oshisayo ukuqinisekisa ukuthi akukho umswakama osele. Lesi sinyathelo sigcina indawo ihlanzekile futhi sivimbela ukugqwala okumhlophe.

- Hlanza ngamanzi amasha

- Yomisa ngomoya oshisayo

- Gcina amapayipi endaweni eyomile

Ukuhlolwa Nokuhlolwa Kwekhwalithi

Kumelwe uhlole amapayipi ukuqinisekisa ukuthi ungqimba luqinile futhi lulingana. Usebenzisa ukuhlola okubonakalayo, izilinganiso zobukhulu, kanye nokuhlolwa kokufana. Uhlola futhi ubulukhuni, ukugqwala, kanye nomonakalo. Ulinganisa usayizi wepayipi bese ubheka ukuvuza. Ulandela izindinganiso ezifana ne-ASTM A500 kanye ne-EN 10219. Lezi zindinganiso zikusiza ukuthi uqinisekise ukuthi amapayipi azohlala isikhathi eside futhi amelane nokugqwala.

Indlela Yokuhlola Incazelo Ukuhlolwa okubonakalayo Hlola ukuthi kubushelelezi, kukhona amaphutha, futhi kukhona ukugqwala Ubukhulu besendlalelo Sebenzisa amamitha ukukala ubukhulu bengubo Ukufana Bheka ukuxebuka noma ukugqoka okungalingani Ubulukhuni Hlola ubulukhuni bomphezulu Ukuhlolwa kokugqwala Thola imihuzuko noma umonakalo Ikhwalithi yokushisela Hlola ukuthi akukho yini imifantu noma i-slag Ukwakheka kwamakhemikhali Hlola ukuthi i-zinc nensimbi zingakanani Ukuziphatha kwemishini Linganisa amandla nokuguquguquka Ukuhlolwa kobukhulu Qinisekisa ububanzi, ukujiya, kanye nobude Ilogo nokumaka Hlola amalebula afanele Ukuhlolwa kokuvuza Qiniseka ukuthi amapayipi awanazo izimfa noma imigodi Isikhumbuzo Sokuphepha: Landela njalo imithetho yokuphepha uma usebenzisa imishini yokugaya i-hot-dip galvanizing yepayipi lensimbi. Hlola amapayipi ukuze ubone umonakalo futhi uqinisekise ukuthi ikhwalithi yamanzi ilungile ukuze uvimbele ukugqwala.

Izinzuzo Zemishini Yokugalela I-Steel Pipe Hot-Dip

Ukuvikelwa Okuphezulu Kokugqwala Nokugqwala

Uthola isivikelo esiqinile ekugqwaleni uma usebenzisaimishini yokugaya i-hot-dip galvanizing yepayipi lensimbi. Isembozo se-zinc sakha isithiyo esikhulu esigcina amanzi, umoya, namakhemikhali kude nensimbi. Lesi sithintelo sisebenza kangcono kunopende noma izembozo ezincane. I-zinc iphinde ivikele insimbi uma isembozo siklwebheka. I-zinc izoqala ngokugqwala, isindise insimbi engaphansi.

- Ungqimba olujiyile lwezinki lumelana nesimo sezulu esibi kanye namakhemikhali.

- Uyabona le ndlela isetshenziswa emabhulohweni, ezinsikeni, kanye namapayipi angaphandle ngoba ihlala isikhathi eside.

- Isembozo se-zinc sisebenzisa kokubili ukuvikela okuvimbelwe kanye nokuvikela okuzidelayo, ngakho amapayipi akho ahlala ephephile noma ngabe indawo yonakele.

Izifundo zesayensi zibonisa ukuthi i-zinc yakha ama-compounds akhethekile, njenge-ZnO kanye ne-Zn5Cl2(OH)8, anciphisa ukugqwala futhi agcine amapayipi eqinile ezindaweni ezinzima.

Indlela yokusebenza Incazelo Ukuvikelwa Kwezithiyo Ungqimba lwezinki luvimba amanzi nomoya ukuthi ungafinyeleli ensimbini. Isivikelo Somhlatshelo I-zinc iyagqwala ngaphambi kwensimbi, iyivikele noma ngabe iklwebhekile. Isimo Sezulu Semvelo Ngokuhamba kwesikhathi, i-zinc yakha izendlalelo ezengeziwe ezinezela isivikelo esengeziwe. Ukuqina Okuthuthukisiwe Nokuphila Isikhathi Eside

Ungalindela ukuthi amapayipi e-galvanized ahlale amashumi eminyaka. Uma ungqimba lwe-zinc lujiyile, kulapho amapayipi akho azohlala khona isikhathi eside. Isibonelo:

Uhlobo Lokumboza Isikhathi Sokuphila Esilindelekile Ezindaweni Eziphakathi G30 Iminyaka emi-5–10 I-G90 Iminyaka engama-20 noma ngaphezulu Amapayipi amaningi e-galvanizing ahlala iminyaka engaba ngu-40 kuya ku-50. Ezindaweni ezomile, angahlala isikhathi eside nakakhulu. Uma usebenzisa imishini ye-galvanizing yepayipi lensimbi, usiza amapayipi akho ukuba amelane nokugqwala nomonakalo iminyaka eminingi.

- Amapayipi ezindaweni ezinomswakama ophansi angahlala iminyaka efinyelela kwengu-70.

- Ezindaweni ezimanzi noma ezinosawoti, isikhathi sokuphila singaba sifushane, kodwa sibe side kakhulu kunensimbi engagqokwanga.

Ukusebenza Kahle Kwezindleko Nokulungiswa Okuphansi

Wonga imali ngokuhamba kwesikhathi ngamapayipi e-galvanized. Izindleko zokuqala ziphakeme kancane kunopende, kodwa usebenzisa imali encane ekulungiseni nasekulungiseni. Nasi isiqhathaniso esisheshayo:

Indlela Yokuvikela Izindleko Zokuqala Isikhathi Sokuphila (iminyaka) Izindleko Zokunakekela I-NPV Ukushisa Okushisayo 100 25 0 100 Uhlelo Lokupenda 90 8 169 169 Amapayipi e-galvanized adinga ukuhlanzwa okuncane nokulungiswa okuncane. Ukwembozwa kwawo okuqinile kusho ukuthi akudingeki ukhathazeke ngokugqwala noma ukuvuza njalo. Lokhu kuwenza abe ukukhetha okuhlakaniphile kwamaphrojekthi amakhulu nezindawo lapho ufuna khona amapayipi ahlale isikhathi eside.

Imishini yokugaya ngogesi eshisayo ikusiza ukuvikela amapayipi ensimbi iminyaka eminingi. Uthola ukusebenza okuthembekile ezindaweni ezahlukene.

- Ukuqina kwesikhathi eside kuncike ezimweni zemvelo.

- Ochwepheshe bathiisinyathelo ngasinye senqubo siyathintaikhwalithi kanye namandla okumboza.

Isinyathelo Umthelela Ekusebenzeni Kahle Ukuhlanza Kuthuthukisa ukunamathela futhi kuvimbela amaphutha Ukukhahlela Kuthinta ukushelela kanye nekhwalithi Ukufudumeza Iqinisekisa ukugeleza kwe-zinc okufanayo Ukucwiliswa Ilawula ukujiya kanye nekhwalithi yangaphakathi Ukuhlolwa Kuqinisekisa ukuthi ukumbozwa kuhlangabezana nezindinganiso

Isikhathi sokuthunyelwe: Septhemba 11-2025