Ufuna ihadiwe ehlala isikhathi eside. Izikulufo ze-galvanized namantongomane zivame ukuqina kunezinketho ezifakwe i-zinc, ikakhulukazi ngaphandle. Bheka nje izinombolo ezingezansi:

| Uhlobo Lwesikulufu/Inathi | Isikhathi Sokuphila Ezicelweni Zangaphandle |

|---|---|

| Izikulufo/Amantongomane Ahlanganisiwe | Iminyaka engu-20 kuya kwengu-50 (yasemakhaya), iminyaka eyi-10 kuya kwengu-20 (yezimboni/yasogwini) |

| Izikulufu Ezifakwe I-Zinc | Izinyanga ezimbalwa kuya eminyakeni emibili (isimo sezulu esomile), ngaphansi konyaka owodwa (onomswakama), izinyanga ezimbalwa kuphela (ogwini) |

Uma usebenzisa kahleImishini Yokubumba Ngezikulufo Nezinathi, uthola isivikelo esithembekile.Imishini Yokubumba Nge-Galvanizingkwenza umehluko ocacile ekuqineni.

Izinto Ezibalulekile Okufanele Uzicabangele

- Izikulufo namantongomane agqitshiweihlala isikhathi eside kakhulu kunezinketho ezifakwe i-zinc, okwenza zibe zilungele amaphrojekthi angaphandle.

- Ukugqoka kwe-zinc kuma-fasteners ahlanganisiwe kuhlinzekaukumelana okuhle kakhulu kokugqwala, zivikele ekugqwaleni ezindaweni ezinzima.

- Ukukhetha ihadiwe elakhiwe nge-galvanized kungaholela ekongeni izindleko ngokuhamba kwesikhathi ngenxa yokunciphisa ukulungiswa kanye nokunciphisa ukushintshwa.

Izinzuzo Eziyinhloko Zama-Screws Nama-Nuts Ahlanganisiwe

Ukumelana Nokugqwala

Ufuna izikulufo namantongomane akho ahlale isikhathi eside, ikakhulukazi ezindaweni ezinzima.Izibambo ze-Galvanisedine-zinc coating ebavikela ekugqwaleni. Lolu ngqimba lusebenza njengesivikelo emswakama namakhemikhali. Ungasebenzisa lezi zikulufo namantongomane ngaphandle, ezindaweni ezinomswakama, noma eduze kolwandle.

Ucwaningo luhlole ukusebenza kokugqwala komoya kwama-bolts ensimbi agqitshwe endaweni yasolwandle iminyaka emibili. Luthole ukuthi uqweqwe lwe-zinc luhlinzeka ngesivikelo esincane kakhulu ku-substrate yensimbi engaphansi, futhi naphezu kokwakheka kwengqimba yokugqwala ebanzi, ukuwohloka kwe-fastener kwakubalulekile, okubonisa ukuthambekela okuphezulu ekukhuculweni kwe-foliation kanye nokuqhekeka kwentambo okungenzeka.

Insimbi egayiwe ayifani nokumelana nokugqwala kwensimbi engagqwali, kodwa isanikeza isivikelo esingcono kunensimbi engenalutho. Ungabona umehluko kuthebula elingezansi:

| Izinto | Ukumelana Nokugqwala | Amanothi |

|---|---|---|

| Insimbi Egayiwe | Ngaphansi kunensimbi engagqwali; ukugqoka kwe-zinc kungaguga okuholela ekugqwaleni | Inketho eshibhile, kodwa engaqinile kakhulu ezindaweni ezinzima. |

| Insimbi engagqwali | Ukumelana okuphezulu kokugqwala ngenxa yesendlalelo se-chromium oxide; ukumelana ngisho noma kuklwejwa | Kubiza kakhulu, kodwa kunikeza ukuqina kwesikhathi eside kanye nokuvikelwa kokugqwala. |

Ukuqina Kwesikhathi Eside

Udinga ihadiwe ehlala isikhathi eside.Izikulufo namantongomane agqitshiweIhlala isikhathi eside kakhulu kunezifakwe i-zinc. Isembozo se-zinc siyabasiza ukuthi bamelane nezimo ezimanzi kanye nesimo sezulu esibi. Ungathembela kuzo kumaphrojekthi angaphandle afana nocingo, amabhuloho, kanye namadekhi.

- Izikulufo eziqinile eziqinile zinikeza amandla amangalisayo nokuqina kumaphrojekthi angaphandle.

- Ziyindlela engcono kakhulu kunensimbi engagqwali, okwenza zibe ukukhetha okuwusizo kwezicelo eziningi.

- Izikulufo ezenziwe nge-galvanized ziyasebenza kumaphrojekthi angaphandle ngenxa yokwembozwa kwazo nge-zinc, okuzisiza ukuthi zimelane nezimo ezimanzi kanye nesimo sezulu esibi.

- Zihlinzeka ngokuxhumana okuqinile kwezakhiwo ezifana nocingo, okwenza kube ukukhetha okuhlala isikhathi eside kwezicelo zangaphandle.

Ungaqhathanisa isikhathi sokuphila sama-fasteners ahlukene:

- Izikulufo ezifakwe i-zinc: iminyaka eyi-10-15 ngaphakathi, iminyaka eyi-1-3 ngaphandle ezindaweni eziveziwe.

- Izikulufo ezifakwe ngogesi ezishisayo: Iminyaka engaphezu kwengu-50 ngaphakathi, iminyaka eyi-10-20 ngaphandle, iminyaka emi-5-7 eduze kolwandle.

- Izikulufo zensimbi engagqwali ezingu-304: Isikhathi sokuphila ngaphakathi endlini, iminyaka engaphezu kuka-30 ngaphandle, iminyaka eyi-10-15 ezindaweni zasolwandle.

- Izikulufo zensimbi engagqwali ezingu-316: Isikhathi sokuphila cishe kuzo zonke izindawo, iminyaka engaphezu kwengu-25 ngasogwini lolwandle.

- Izikulufo zethusi ze-silicon: iminyaka engaphezu kuka-50 emanzini anosawoti.

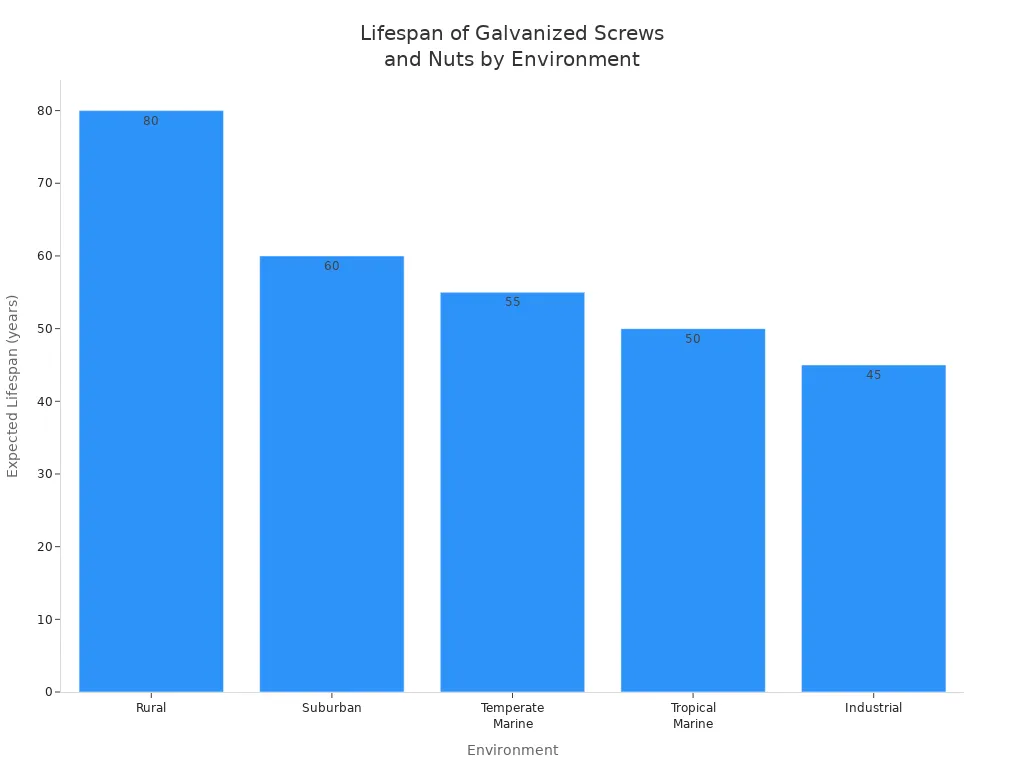

Izikulufo namantongomane agqitshwe nge-galvanized angahlala amashumi eminyaka ezindaweni eziningi. Ishadi elingezansi libonisa ukuthi ungalindela ukuthi ahlale isikhathi esingakanani:

| Indawo ezungezile | Isikhathi Sokuphila Esilindelekile |

|---|---|

| Ezasemakhaya | Iminyaka engaphezu kuka-80 |

| Idolobha elingaphansi komhlaba | Iminyaka engaphezu kuka-60 |

| I-Temperate Marine | Iminyaka engu-55+ |

| I-Tropical Marine | Iminyaka engaphezu kuka-50 |

| Izimboni | Iminyaka engu-45+ |

Ukonga Izindleko Ngokuhamba Kwesikhathi

Wonga imali uma ukhetha izikulufo nama-nuts agqitshiwe. Lezi zinamathiseli zidinga ukulungiswa okuncane kanye nokufakwa okuncane. Uchitha imali encane ekulungiseni nasekusebenzeni eminyakeni edlule.

- Izindleko Zokulungisa Ezincishisiwe: Insimbi egayiwe idinga ukulungiswa okuncane kakhulu phakathi nesikhathi sayo sokuphila, okuholela ekongeni okukhulu ezindlekweni zokulungisa.

- Isikhathi Sokuphila Eside: Isikhathi eside sokuphila kwensimbi ekhandiwe kunciphisa isidingo sokushintsha njalo, okubangela ukonga izindleko.

Uthola inani elithe xaxa ngokutshala kwakho imali. Ihadiwe eyenziwe nge-galvanized ikusiza ukuthi ugweme izindleko ezingalindelekile futhi igcine amaphrojekthi akho eqinile iminyaka eminingi.

Ukuguquguquka Ezindaweni Ezihlukene

Ungasebenzisa izikulufo ezifakwe ugesi namantongomane ezindaweni eziningi. Zisebenza kahle ngaphandle, ezindaweni ezimanzi, nasezindaweni ezinesimo sezulu esishintshayo. Ukwembozwa kwazo nge-zinc kuzenza zibe yisinqumo esihle kakhulu kumaphrojekthi okwakha nawangaphandle.

Izikulufo namantongomane e-galvanized asebenza kahle kakhulu ezindaweni zangaphandle nezinomswakama ophezulu ngenxa yokuqina kwawo okuthuthukisiwe kanye nokumelana nokugqwala, okwenza kube ukukhetha okuthandwayo kumaphrojekthi okwakha nawangaphandle.

Izimboni eziningi zithembele ku-hardware eyenziwe nge-galvanized ngoba ivumelana nezimo ezahlukene. Ungabona ukusetshenziswa okuvamile kuthebula elingezansi:

| Imboni | Incazelo Yesicelo |

|---|---|

| Isakhiwo | Isetshenziswa ekuhlanganisweni kohlaka kanye nemishini yenjini, ihlinzeka ngokumelana nokudlidliza, ukushisa kanye nomswakama. |

| Izimoto | Kubalulekile ezingxenyeni ezahlukene, ukuqinisekisa ukuqina nokusebenza kahle kwezindleko. |

| Ezolimo | Isetshenziswa ekulungiseni imishini nemishini, ivezwe emswakama namakhemikhali, ithuthukisa isikhathi sokuphila. |

| Izimboni Zasogwini | Kuwusizo ngenxa yokwembozwa kwe-zinc okuvikela ekugqwaleni kwamanzi anosawoti. |

| Izimboni | Kubalulekile emishinini yokubopha, izinhlaka zensimbi, kanye nezinhlelo ze-HVAC ezindaweni ezinzima. |

Ungathemba izikulufo eziqinisiwe namantongomane ukuthi zisebenze ezindaweni eziningi, kusukela emapulazini kuya ezimbonini kuya ezakhiweni ezisogwini.

Izingqinamba Eziyinhloko Zehadiwe Elakhiwe Ngogesi

Ingozi Yokuqhekeka Kwe-Hydrogen

Udinga ukwazi mayelanaukuqhekeka kwe-hydrogenngaphambi kokukhetha izikulufo ezihlanganisiwe namantongomane. Le nkinga yenzeka lapho i-hydrogen ingena ensimbini bese iyenza iqhekeke. Insimbi eqhekekile ingaqhekeka noma iphuke ngaphansi kokucindezeleka.

Izici eziningana zandisa ingozi yokuqhekeka kwe-hydrogen:

- Ukugqwala, ikakhulukazi ezindaweni ezine-asidi noma ezinosawoti, kukhiqiza i-hydrogen ezindaweni zensimbi.

- Umswakama udlala indima enkulu, ikakhulukazi ezindaweni ezinomswakama ophezulu.

- Ukuchayeka ngesikhathi sokwakha, njengokusebenza ezimweni ezimanzi, kungasheshisa ukungena kwe-hydrogen.

- Izimo zesevisi ezinamazinga angaqinisekile noma aphezulu omswakama ziphakamisa ingozi.

Ubhekene nengozi enkulu uma lezi zinto ezintathu zenzeka ndawonye:

- I-hydrogen ikhona.

- I-fastener ingaphansi komthwalo noma ukucindezeleka okuqhubekayo.

- Izinto ezibonakalayo ziyathinteka kalula, ikakhulukazi insimbi enamandla kakhulu.

Ukucindezeleka okungahlosiwe ngesikhathi sokufakwa kungacindezela kakhulu izikulufo futhi kwenze kube lula ukubhidlika. Kufanele uhlale ulawula imithombo yokucindezeleka futhi ugweme ukuqinisa kakhulu izibambo.

Icebiso:Uma usebenzisa izibambo ze-galvanized ezindaweni ezimanzi noma ezigqwalayo, hlola izimpawu zokuqhekeka noma ukulahleka kwamandla ngokuhamba kwesikhathi.

Izinkinga Zokubopha Ezivela Kubukhulu Bokumboza Nge-Zinc

Izikulufo ezihlanganisiwe namantongomane zinoqweqwe oluqinile lwe-zinc. Lokhu qweqwe kuvikela ekugqwaleni, kodwa kungabangela izinkinga uma uzama ukubopha izingxenye ndawonye. Ubukhulu besendlalelo se-zinc bungenza izikulufo namantongomane kube nzima ukungena emigodini noma ezintanjeni.

| Isici | Imininingwane |

|---|---|

| Ubukhulu be-Zinc CoatingIbanga | 45–65 μm |

| Umthelela Ekuqiniseni | Izembozo ezijiyile zidinga ukuthepha ngaphezulu kwemigodi ukuze ilingane nezibambo, okuthinta ukubopha okuqinile. |

| Ukuvikelwa Kokugqwala | Ukwembozwa kwe-zinc ezintanjeni zesilisa kuvikela zombili izingxenye ekugqwaleni naphezu kokuthepha ngokweqile. |

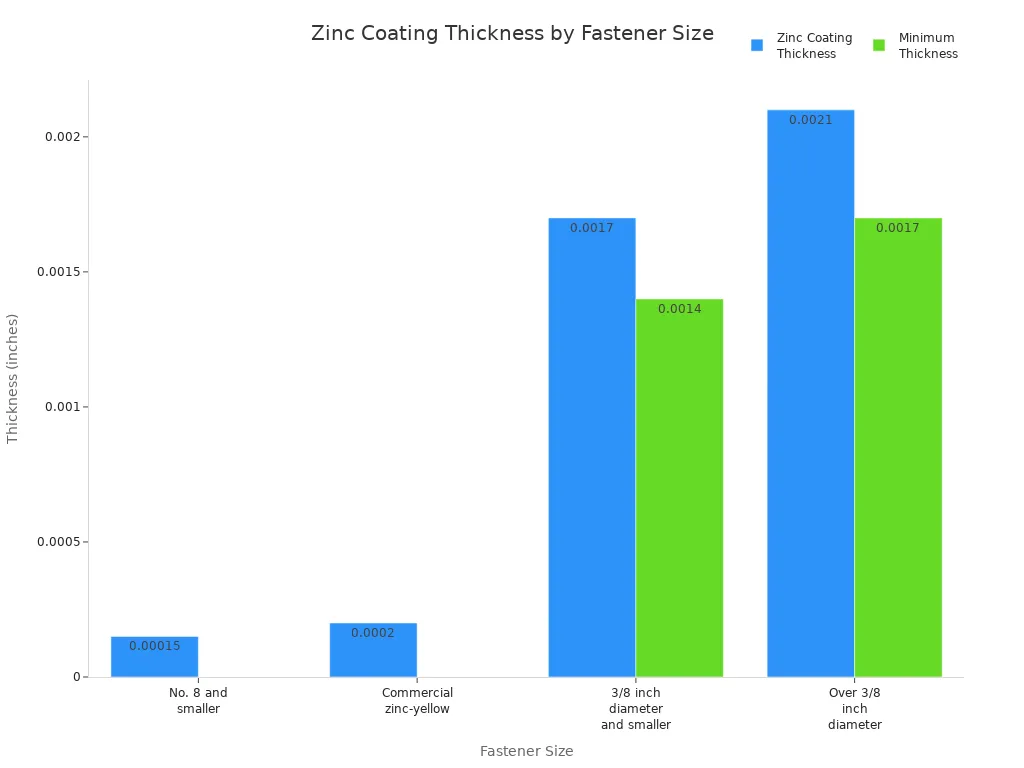

Izindinganiso zemboni zibeka imingcele yobukhulu be-zinc coating ukuvimbela izinkinga zokubopha. I-zinc plating ivame ukunikeza ungqimba oluncane nolucwebezelayo, oluhle kuma-fasteners amancane ezimweni ezithambile. I-hot-dip galvanizing idala ungqimba olujiyile kakhulu, olusebenza kangcono ezindaweni ezinzima kodwa lungenza ukubopha kube nzima kakhulu.

| Usayizi Wokubopha | Ubukhulu be-Zinc Coating (amasentimitha) | Ubukhulu Obuncane (amasentimitha) |

|---|---|---|

| Inombolo 8 noma ngaphansi | 0.00015 | Ukugqoka okuncane kuyamukeleka |

| I-zinc-yellow yezentengiselwano | 0.00020 | Ukugqoka okuncane kuyamukeleka |

| Ububanzi obungu-3/8 intshi futhi buncane | 0.0017 | 0.0014 |

| Ububanzi obungaphezu kuka-3/8 intshi | 0.0021 | 0.0017 |

- I-zinc plating yezentengiselwano inobukhulu obuncane obungamasentimitha angu-0.00015.

- I-hot dip galvanizing inikeza ungqimba olujiyile noluhlala isikhathi eside, oluwugqinsi olucishe lube ngu-1.0 mm.

- Izinamathiseli ezifakwe i-zinc zisebenza kahle ezindaweni ezithambile, kodwa izinamathiseli ezifakwe i-galvanized ezishisayo zingcono ezimweni ezinzima.

Akufanelekile Ukusetshenziswa Ngengcindezi Ephakeme

Izikulufo namantongomane awenzi kahle ezisetshenziswayo ezicindezela kakhulu noma ezithwala umthwalo. Ungase ubone izinkinga ezifana nokuqhekeka noma ukwehluleka okungazelelwe uma uzisebenzisa lapho kukhona amandla aqinile.

Ingozi yokuqhekeka kwe-hydrogen iphakeme kakhulu kuma-fasteners anamandla okudonseka angaphezu kuka-150 ksi. Le nkinga ibangela ukuthi insimbi ilahlekelwe ukuguguleka futhi iphuke kusenesikhathi. Izindinganiso zemboni, njenge-ASTM A143 kanye ne-ASTM F2329, zixwayisa ngokusebenzisa ama-fasteners ashisayo afakwe e-galvanized emisebenzini enamandla aphezulu.

Ezindaweni ezixinene kakhulu, amabhawodi agqitshiwe angaba nenkinga yokuqhekeka kokugqwala kokucindezeleka kanye nokuqhekeka okubangelwa yi-hydrogen. Amandla awo angehla ngaphezu kuka-20% ngemva kokusetshenziswa isikhathi eside. Okuqukethwe kwe-hydrogen kula mabhawodi kunganda ngaphezu kuka-300%, okwenza kube lula ukuthi ahluleke. Amabhawodi agqitshiwe aqinile agcina izakhiwo zawo zemishini zingcono ngaphansi kokucindezeleka.

Qaphela:Uma ufuna amabhuloho, imishini esindayo, noma izisekelo zesakhiwo, kufanele ukhethe izibambo ezenziwe ngezinto eziqinile njengensimbi engagqwali noma insimbi ye-alloy.

Ukukhathazeka Ngokuhambisana Nezinye Izinto

Kumelwe ucabangele ukuhambisana uma usebenzisa izikulufo ezihlanganisiwe kanye namantongomane nezinye izinto zokwakha. Ezinye izinhlanganisela zingabangela ukugqwala noma ukusabela kwamakhemikhali okwenza iphrojekthi yakho ibe buthaka.

Imithombo eminingana ezimele iye yaxwayisa ngokuthi ukugqwala okumhlophe nokubomvu kwakheka ngokushesha lapho izikhonkwane ezifakwe ngogesi ezishisayo zihlolwa ngokhuni oluphathwe ngendlela engasebenzisi i-arsenate. Ngokusho kombiko we-EPA, '[t]nansi ukuhlolwa okusheshisiwe okwenziwa yimboni yokwakha okubonisa ukuthi ngisho nehadiwe ekhangisa ukumelana okuthuthukisiwe nokugqwala iqala ukubonisa izimpawu zokugqwala zingakapheli amahora ayi-1000 okuhlolwa okusheshisiwe okwenziwa (okulingana neminyaka eyi-16 yokuchayeka okufakiwe) uma isetshenziswa ngokhuni oluphathwe nge-ACQ.'

- Ukhuni olulungisiwe oluvikelayo lungangahambisani nezikulufo ezifakwe i-zinc kanye ne-aluminium.

- Izikhonkwane zensimbi engagqwali noma izipikili ezifakwe i-hot dip galvanized ezenziwe nge-ASTM A153 Class D noma ezisindayo zisebenza kangcono ngokhuni olulungisiwe.

- Uma unamathisela amaphaneli ensimbi okhunini olulungisiwe, ungasebenzisa isithiyo somswakama phakathi kwezinkuni kanye nephaneli.

- Izibambo ezingahambisani zifaka phakathi izikulufo ezifakwe i-zinc plated, izikulufo ezine-zinc-alloy headed, kanye nezikulufo ezinezivalo ezingagqwali.

Ukusabela kwamakhemikhali nakho kungenzeka phakathi kokumbozwa kwe-galvanized kanye nekhonkrithi, ikakhulukazi ngesikhathi sokuqina. Le nqubo ikhipha igesi ye-hydrogen futhi inciphise isibopho phakathi kwe-galvanized rebar kanye nekhonkrithi. Ukwelashwa nge-chromate kusiza ukunciphisa lezi zinkinga.

Isexwayiso:Hlola njalo ukuthi izibambo zakho ziyahambisana yini nezinto ezikuphrojekthi yakho. Ukusebenzisa inhlanganisela engalungile kungaholela ekugqwaleni kwasekuqaleni, ekubuthakathakeni kwamalunga, noma ngisho nasekuhlulekeni kwesakhiwo.

Isikhathi Sokusebenzisa Izikulufo Namantongomane Ahlanganisiwe

Izinhlelo Zokusebenza Ezinhle Kakhulu Zephrojekthi

Uthola inani elikhulu kakhulu ku-izikulufo ezihlanganisiwe namantongomanekumaphrojekthi abhekene nesimo sezulu, umswakama, noma ukuchayeka ngaphandle. Ochwepheshe bemboni batusa lezi zinamathiselo ukuze zisetshenziswe kaningana:

- Amaphrojekthi Angaphandle: Ungasebenzisa izikulufo ze-galvanized zocingo, amadekhi, kanye nefenisha yangaphandle. Ukumelana kwazo nokugqwala kugcina umsebenzi wakho uqinile ngisho noma lina noma likhanya ilanga.

- Amaphrojekthi Okwakha: Abakhi bavame ukukhetha izikhonkwane ze-galvanized zohlaka lwesakhiwo kanye nokwakhiwa okuvamile. Uyazuza ngokuqina kwazo kanye nezindleko eziphansi.

- Umsebenzi Wokhuni Nokuhlobisa: Izikulufo ezifakwe i-galvanized zisebenza kahle ngokhuni olulungisiwe. Zisiza ekuvimbeleni amabala kanye nokulimala kokhuni ngokuhamba kwesikhathi.

Icebiso:Amakhodi okwakha avame ukudinga izibambo zensimbi engagqwali, noma zethusi ze-silicon ezicwiliswe ngokushisa kumaphrojekthi anezinkuni ezilungisiwe. Ukuze uphahla, kufanele usebenzise izibambo zensimbi ukuze uhlangabezane nezindinganiso zokuphepha.

| Uhlobo Lohlelo Lokusebenza | Isidingo Sokubopha |

|---|---|

| Uphahla | Izibambo ze-galvanized zophahla lwensimbi |

| Ukhuni Oluphathwa Ngokulondoloza | Kudingeka insimbi egayiwe ecwiliswe ngokushisa, insimbi engagqwali, ithusi le-silicon, noma izibambo zethusi. |

Isikhathi Sokucabangela Ezinye Izindlela

Kufanele ubheke ezinye izinhlobo zezibambo uma iphrojekthi yakho ibhekene nokucindezeleka okukhulu, amakhemikhali, noma amanzi anosawoti. Izibambo zensimbi engagqwali zisebenza kahle kakhulu ezindaweni zasolwandle, ekucubungulweni kokudla, noma ezindaweni zezokwelapha. Zihlala isikhathi eside futhi zimelana nokugqwala kangcono kunensimbi egayiwe, ikakhulukazi ezindaweni ezinzima.

| Uhlobo Lokubopha | Okuhle Kakhulu Kwaba | Ochwepheshe | Ububi |

|---|---|---|---|

| Insimbi engagqwali | Imikhumbi, ukudla, ezokwelapha, ngaphandle | Ihlala isikhathi eside, ayigqwali | Izindleko eziphezulu |

| I-Zinc Plating | Izindawo ezomile nezithambile | Ukuvikelwa kokugqwala okungabizi futhi okuyisisekelo | Akuyona indawo emanzi noma enzima |

| Isimbozo se-Phosphate | Ezempi, ezimoto, ezimbonini | Ukugcotshwa okuhle ngamafutha | Ukumelana nokugqwala okumaphakathi |

Izembozo ze-galvanized zivikela insimbi emanzini olwandle, kodwa usawoti namakhemikhali kungazigugisa ngokushesha. Insimbi engagqwali inikeza ukusebenza okungcono kwesikhathi eside kulezi zindawo ezinzima. Khetha isinamathiseli esifanele sendawo yakho ukuze ugcine iphrojekthi yakho iphephile futhi iqinile.

Ukukhetha Izibambo Eziqinile Ezisezingeni Eliphezulu

Isikhathi sokuthunyelwe: Septhemba-24-2025