Ukugaya nge-galvanizing kuyindlela esetshenziswa kakhulu yokuvikela insimbi ekugqwaleni. Ngokuyisisekelo,ukugeza nge-galvanizingikettle enkulu ye-zinc encibilikisiwe esetshenziselwa ukumboza izingxenye zensimbi. Uma insimbi ehlanzekile ifakwa kuleli bhavu, i-zinc inamathela ngokushesha ebusweni, yakhe isiphetho esiqinile, esingagqwali. I-Galvanizing ibilokhu ikhona iminyaka engaphezu kwe-150, kodwa ihlala isebenza kahle ngokumangalisayo futhi inobungani nemvelo. Eqinisweni, ivame ukubizwa njengenye yezinqubo zokuvimbela ukugqwala ezinobungani nemvelo ezitholakalayo. Umphumela uba yinsimbi engaphila amashumi eminyaka ngaphandle ngaphandle ngaphandle kokunakekelwa okuncane. Ngezansi sichaza isinyathelo ngesinyathelo ukuthi ingxenye yensimbi ishintsha kanjani isuka ensimbini endala enothuli iye evikelwe nge-zinc, ngaphakathi kwebhavu elivikelwe nge-galvanizing.

Iyini Ibhavu Elisebenzisa I-Galvanizing?

Ibhavu lokugeza elisebenzisa i-galvanizing limane nje liyi-vat ye-zinc encibilikisiwe eshiswa cishe ku-450°C (842°F). Izingxenye zensimbi zehliswa kule zinc eshisayo, ebukeka njengensimbi ewuketshezi yesiliva. Ngesikhathi sokucwiliswa, i-zinc isabela nensimbi ensimbini, okudala isibopho sensimbi phakathi kwe-zinc nensimbi. Empeleni, izinkampani zivame ukubiza lokhu ngokuthiukucwilisa okushisayoinqubo – ukufaka insimbi ngokoqobo kuzinki “eshisayo” (encibilikisiwe).

Le ndlela iyasebenza kakhulu. Ibhavu le-zinc livame ukugcina i-zinc emsulwa engaphezu kuka-98%, futhi izinhlelo zokuthutha noma ze-crane zigoba ngokucophelela izingcezu zensimbi ukuze i-zinc ikwazi ukugcwala yonke indawo yengxenye. Ngisho nezimo noma amashubhu angenalutho agcwala i-zinc, ngakho ingaphakathi limbozwe kanye nengaphandle. Njengoba omunye umhlahlandlela wemboni ekubeka, i-hot-dip galvanizing iyinqubo "yokucwiliswa ngokuphelele" - insimbi icwiliswa ngokuphelele futhi i-zinc coatskonkeIngaphakathi nengaphandle. Insimbi iphakanyiswa ngemva kwemizuzu embalwa inesikhumba esisha sensimbi esicwebezelayo kuyo.

Inqubo Yokucwilisa Ngokushisa (Qala Kuze Kuphele)

Inqubo yokwenza i-galvanizing inezigaba eziningana ezibalulekile. Ngayinye kumele yenziwe ngokucophelela, ngoba i-zinc izonamathela kuphela endaweni ehlanzekile ngokuphelele. Ngokuvamile, lezi zinyathelo yilezi:

Ukuhlanza (Ukususa amafutha kanye nokuwagaya):Okokuqala insimbi ihlanzwa kahle ukuze kususwe amafutha, amafutha kanye nokugqwala okuxekethile. Lokhu kuvame ukuhilela isisombululo esishisayo se-alkali (caustic) esisusa amafutha ensimbini. Okulandelayo, insimbi iya ebhavini lokuthosa i-asidi (ngokuvamile incibilikisa i-sulfuric noma i-hydrochloric acid) ukuze idle isikali se-mill kanye nokugqwala. Ngemva kokuthosa, noma yikuphi ukungcola okuqinile, upende noma i-slag kususwa ngesandla noma ngokuqhumisa. Ngamafuphi, konke ukungcola kumele kuphele, ngoba i-zinc ngeke ihlangane nensimbi engcolile.

Ukushintshashintsha:Ngaphambi nje kokufaka i-galvanizing, insimbi ehlanzekile ifakwe esixazululweni se-flux, ngokuvamile ingxube ye-zinc ammonium chloride. I-flux ihlanza amachashazi okugcina e-oxide futhi ivimbele i-oxidation entsha ngaphambi kokucwilisa. Kwezinye izitshalo, "ingubo ye-flux" encane intanta ngisho naphezu kwebhavu le-zinc ukusiza ukwehlisa amafutha ensimbi njengoba ingena. Isinyathelo sokucwilisa sibalulekile: siqinisekisa ukuthi ithini le-zinc elincibilikisiwemanziinsimbi ngokulinganayo.

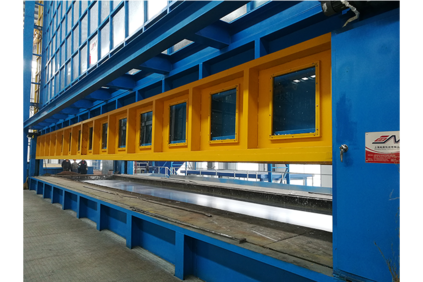

Ukucwiliswa ebhavini leZinc:Manje sekuza inhliziyo yenqubo. Insimbi elungisiwe yehliswa kancane kancane (ngokuvamile nge-engeli) eketheni le-zinc elicibilikisiwe, elivame ukubanjwa ku-~450°C. Isithombe esingezansi sibonisa imishayo yensimbi ingena ebhavini le-zinc elishisayo. Lapho nje insimbi ithinta insimbi ewuketshezi, kuqala ukusabela. I-Zinc iqala ukuxubana nobuso bensimbi, bese i-zinc ewuketshezi igeleza yonke ingxenye. Ngaphakathi ebhavini, i-zinc nensimbi kwakha izendlalelo eziningana ze-alloy ngokusabela kwe-metallurgical. Phakathi nalesi sikhathi (ngokuvamile imizuzu embalwa), ungqimba lukhula lube ugqinsi olufanele. Isendlalelo seokuncibilikisiwei-zinc inamathela ebusweni bensimbi bese iphola ukuze yakhe isikhumba sangaphandle esiqinile.

Umfanekiso: Izingxenye zensimbi zicwiliswa ebhavini elishisayo elifaka i-galvanizing. I-zinc encibilikisiwe (isiliva eliwuketshezi) ivala insimbi ngokushesha.

Abasebenzi bezitshalo babeka isikhathi sokucwilisa ngokucophelela. Ezindaweni eziningi, ukucwilisa imizuzu engu-4-5 kwanele. Izingxenye ezinkulu noma ezivikelwe zingadinga isikhathi eside ukuze zifinyelele izinga lokushisa eligcwele. Uma sezishisiwe, ingxenye iyaphakanyiswa kancane kancane. Njengoba ikhuphuka, noma iyiphi i-zinc eningi iyaphuma - ngezinye izikhathi isizwa ukudlidliza noma ukusonta ingxenye. Igobolondo elincane le-zinc elisele lizophola futhi liqine, livame ukuba nokukhanya okukhanyayo kwesiliva ngaphandle. Eqinisweni, insimbi esanda kufakwa ensimbini ivame ukukhanya; "iphethini" eliyisici noma iphethini efana neqhwa le-zinc ekristalisiwe ingavela ebusweni njengoba iqina.

Ukupholisa (Ukudlulisa/Ukucima):Ngemva kokukhipha, insimbi emboziwe iyapholiswa. Lokhu kungenziwa ngokupholisa umoya okulula noma ngokucima insimbi eshisayo emanzini noma ukugeza ngamakhemikhali. Akukho ukuqina okukhethekile okudingekayo - isibopho se-zinc/steel sesivele siqinile. Noma yiluphi ungqimba oluncane lwangaphandle lwe-zinc oxide (ukugqwala okumhlophe) olungakheka luvame ukushiywa lodwa noma luphathwe kancane. Ngokungafani nezingxenye ezipendiwe, insimbi eboshwe nge-galvanized ivame ukudingaakukho okunye ukuqedaukuze kuhlale isikhathi eside.

Ukuhlolwa:Isinyathelo sokugcina ukuhlola okusheshayo okubonakalayo nobuchwepheshe. Abahloli bahlola ukuthi yonke indawo imboziwe futhi balinganise ukujiya. Njengoba i-zinc ibopha kuphela ensimbini ehlanzekile, kulula ukubona izindawo ezimbi (insimbi engenalutho ibukeka ikhanya). Amageyiji ajwayelekile alinganisa ukujiya kokumboza ukuqinisekisa ukuthi ihlangabezana nezidingo. Kuleli qophelo insimbi ehlanganisiwe isilungele ukusetshenziswa, iqinisekisiwe ukuthi izomelana nokugqwala iminyaka eminingi.

Ngaphakathi Ebhavini: Insimbi Nokuvikelwa

Okwenzeka ngempela ensimbini engaphakathi kwe-zinc encibilikisiwe kuyinhlanganisela eyinkimbinkimbi yamakhemikhali - futhi ingenye yamandla amangalisayo e-galvanizing. Njengoba insimbi eshisayo ihlala ebhavini, ama-athomu e-zinc ayasakazeka abe yinsimbi ukuze akhe ama-compounds amaningana e-intermetallic. I-American Galvanizers Association ikhombisa lokhu ngesigaba esiphambene: kukhona ungqimba lwangaphandle lwe-zinc ecishe ibe msulwa (olubizwa ngokuthi ungqimba lwe-eta) kanti ngaphansi kwalo kunezingqimba ezintathu ze-alloy eqinile (ebizwa ngokuthi i-gamma, i-delta, i-zeta) khona kanye esibonakalayo sensimbi. Okuphawulekayo ukuthi lezi zingqimba ze-alloy ze-zinc-iron ziyikunzima kunensimbi ethambileIsibonelo, imihuzuko emincane ayingeni kalula kule ngubo enezingqimba eziningi. Empeleni, ingubo ehlanganisiwe iqinile kakhulu futhi ayikhubeki.

Enye inzuzo ebalulekile ukuvikelwa kwe-cathodic (umhlatshelo). I-Zinc isebenza kakhulu ngamakhemikhali kunensimbi. Kalula nje, uma ungqimba luklwejwa lube yinsimbi engenalutho, i-zinc ezungezile izoklwebheka kuqala, ivikele insimbi. Eqinisweni, i-hot-dip galvanizing idumile ngalokhu: omunye umthombo uphawula ukuthi noma ngabe insimbi engenalutho (enkulu njenge-¼ intshi) ivezwa ekuklwebhekeni, "akukho ukugqwala okuzoqala kuze kube yilapho yonke i-zinc ezungezile isidliwe". Lokhu kusho ukuthi ama-nick amancane awadingi ukupenda kabusha; i-zinc iyazidela ngokuhamba kwesikhathi.

Ngokuhamba kweminyaka ukuchayeka emoyeni nasemvuleni kuguqula i-zinc ibe yimikhiqizo engeyona ingozi (ama-oxide, ama-hydroxide, ama-carbonate) - i-patina empunga ongase uyibone ensimbini endala ekhanyisiwe. i-zinc patina Kancane kancane kwakha uqweqwe lwangaphandle oluvikelayo olunciphisa ukugqwala. Eqinisweni, insimbi egayiwe ngokuphelele igqwala cishe izikhathi ezingu-30 kunensimbi engenalutho. Empeleni, lokhu kusho ukuthi uqweqwe olugayiwe luvame ukuhlala iminyaka engu-50-60 noma ngaphezulu ngaphandle kokunakekelwa, kuye ngendawo ezungezile.

Izinzuzo Ezimangalisayo Ze-Ukuhlanganisa nge-galvanizing

I-Galvanizing inikeza izici eziningana "ezimangalisayo" ongase ungazilindele kusuka ekumbozweni kwensimbi okulula:

1. Ukumbozwa Okuphelele:Ngenxa yokuthi i-hot-dip galvanizing ifaka ingxenye, imboza ngisho nengaphakathi lezingxenye ezingenalutho kanye nengaphakathi lamapayipi. Imicu namakhona afihliwe athola i-zinc, ngokungafani nopende olufakwe ibhulashi. Lokhu kucwiliswa ngokuphelele kusho ukuthi ukugqwala akukwazi ukungena kusuka ezindaweni ezingalindelekile.

2. Ukuqina Okuhlanganisiwe:Izendlalelo ze-zinc-iron ziqinile ngokwemvelo futhi azikwazi ukuguguleka. Kwezinye izivivinyo, ukugqoka kwensimbi ehlanganisiwe kwaphelaizikhathi eziyishumiukumelana nokuguguleka kakhulu kunopende ojwayelekile. Ingqimba yangaphandle ye-zinc emsulwa (eta) ithambile futhi ithambile, inika ukumelana nokushayisana, kuyilapho izingqimba zangaphakathi ze-alloy ziqinile kunensimbi. Lokhu kubopha okunezingqimba eziningi kusho ukuthi izingxenye ezihlanganisiwe zisinda ekuphathweni nasekugugeni okunzima.

3. Ukuzivikela Kokuziphilisa (kwamaKatolika):Njengoba kuphawuliwe, i-zinc "izozidela" ukuze ivikele insimbi. Imihuzuko emincane ensimbini ehlanganisiwe ayigqwali ngoba i-zinc iyagqwala kuqala (ebizwa nangokuthi ukuvikelwa kwe-cathodic). Kukhona ngisho negama elithi, "sideways creep," lalokho okwenzeka ngensimbi edwetshiwe (ukugqwala okukhasa ngaphansi kopende) - futhi ukugqwala kuyakuvimbela.

4. Ukuguquka Okusheshayo:Naphezu kwemishini esindayo, isinyathelo sangempela sokufaka i-galvanizing sishesha. Ukulengisa ucezu bese ucwilisa ku-zinc kuthatha imizuzu embalwa kuphela. Ukulungiselela ikakhulukazi ukuhlanza ngamakhemikhali, futhi isitshalo esisebenza kahle singacubungula i-oda ezinsukwini ezimbalwa sezizonke. Eqinisweni, izitolo zesimanje zokufaka i-galvanizing zinenkonzo yamahora angama-24 yama-oda amancane.

5. Impilo Yesevisi Ende:Ukwembozwa nge-galvanized kungavikela insimbi amashumi eminyaka ngaphandle kokupenda kabusha. Ezimweni ezivamile zangaphandle (zezimboni noma zasemakhaya), kuvamile ukubona iminyaka engaphezu kwengu-50 ngaphambi kokulungiswa kokuqala. Lokhu kuphila isikhathi eside kuvame ukwenza ukupenda nge-galvanized kube okonga kakhulu kunokupenda kabusha ngezikhathi ezithile ngokuhamba kwesikhathi.

6. Ubungane Bemvelo:Inqubo yokwenza i-galvanizing ihlanzekile impela. I-zinc esetshenzisiwe iyasetshenziswa kabusha, futhi azikho izinyibilikisi eziphilayo eziguquguqukayo njengasependeni. Insimbi eyenziwe nge-galvanizing ingaphinde isetshenziswe ngo-100% ekupheleni kokuphila. Amaqembu ezimboni aze aqaphele ukuthi ukwenza i-galvanizing “mhlawumbe kuyindlela yokuvikela ukugqwala enobungani nemvelo” etholakalayo.

7. Ukuqeda Okubonakalayo:Insimbi egayiwe ivame ukuba nesicii-spanglednoma iphethini efana neqhwa ebusweni bayo. Lawa makristalu esiliva ayizinhlayiya ze-zinc eziqina, futhi anikeza ubuso obuhlanganisiwe ukubukeka okuhlukile. Kuyisibonakaliso esibonakalayo sokuthi kukhona ungqimba lwangempela lokucwilisa olushisayo.

Imishini Esezingeni Eliphezulu: Isitshalo Sokugaya Amapayipi sikaBonan Tech

Izitolo ezinkulu zokufaka ugesi zisebenzisa imishini enzima ukuqhuba lezi zinqubo njalo. Isibonelo, iBonan Technology Co., Ltd., umenzi wemishini, igcizelela"Isitshalo Sokugaya Amapayipi Esisezingeni Eliphezulu"zakhiwe ngensimbi esezingeni eliphezulu kanye nezingxenye. Imigqa yazo ezenzakalelayo iphatha yonke into: ama-jig okulengisa amapayipi, amathangi okususa amafutha e-alkali, ama-pickle e-asidi, iziteshi zokuhambisa amanzi, i-conveyor nge-zinc kettle, kanye namathangi okucima ugesi. UBonan uphawula ukuthi izitshalo zayo zokugaya amapayipi zenzelwe ukukhiqizwa okuqhubekayo kuwo wonke amadayamitha amapayipi.

Umfanekiso: Umugqa wokugaya ipayipi oqhubekayo osebenzayo. Izitshalo ezinjalo ezizenzakalelayo zihambisa izingxenye zamapayipi ngokuhlanza, ukugeleza, kanye nobhavu we-zinc oncibilikisiwe.

Kulayini we-Bonan Tech, isinyathelo ngasinye silawulwa ngokucophelela. Eqinisweni, ukugaya amapayipi ngokuvamile kulandela lezi zigaba ezithile:

Ukuhlanza Okubangela Ubuhlungu:Amapayipi angena ebhavini elishisayo le-sodium-hydroxide ukuze asuse isikali samafutha kanye nesigayo.

Ukuqoqwa kwe-Acid:Okulandelayo, badlula ebhavini le-asidi (ngokuvamile i-HCl noma i-H₂SO₄) ukuze bancibilikise ukugqwala kanye nama-oxide asele.

Ukuhlanza Nokufudumeza:Ngemva kokuhlanza, amapayipi acwiliswa kwisisombululo se-zinc-ammonium chloride flux, ukuqinisekisa ukuthi insimbi ihlala ingenayo i-oxide ngaphambi kokusebenzisa i-galvanizing.

Ukomisa:Noma yimuphi umswakama osensimbini uyapheshulwa noma ushiswe umshini wokomisa umoya.

Ukucwiliswa (i-Zinc Bath):Amapayipi afakwa eketheni le-zinc elincibilikisiwe. I-hot dip iwamboza kahle nge-zinc.

Ukucima:Ekugcineni, amapayipi ashisayo agqunywe nge-galvanized apholiswa ngokushesha emanzini noma ebhavini lokucima ukuze kuboshwe ungqimba.

Wonke amapayipi avelayo manje ane-zinc coating efanayo ukuvimbela ukugqwala. Ngokusho kwencazelo kaBonan,"Umshini Wokugalela Ngogesi Ozenzakalelayo Wamapayipi"iyakwazi ukuphatha “uhla lonke lwamapayipi okufanele afakwe i-galvanized”, iqinisekise ukuthi ngisho namapayipi amakhulu kakhulu noma amancane athola ungqimba lwe-zinc olufanele.

Isiphetho

Ibhavu lokugeza nge-galvanizing lingaphezu nje kwebhodwe lensimbi – liyisikhungo senqubo eqinisekisiwe, eqhutshwa yisayensi enikeza insimbi isivikelo esicishe sizilungise. Kusukela ezigabeni zokuhlanza kuya ekucwilisweni kwe-zinc eshisayo, isinyathelo ngasinye senzelwe ukukhiqiza ungqimba oluqinile, oluboshwe ngensimbi. Sibonile ukuthi insimbi egayiwe ayigcini nje ngokumelana nokugqwala kodwa yenza kahle ngokumangalisayo – nge-alloys enezingqimba eziningi, ukuqina okukhulu, kanye neminyaka yokusebenza.

Kungakhathaliseki ukuthi ungunjiniyela ochaza ibhuloho noma umninikhaya okhetha izinsika zocingo, ukuqonda inqubo yokugeza nge-galvanizing kusiza ukuchaza ukuthi kungani insimbi ehlanganisiwe isebenza kahle kangaka. Ngamafuphi, ngaphakathi kwalelo bhavu elincane le-zinc encibilikisiwe kukhona uhlelo lokuzivikela olunamandla noluyinkimbinkimbi ngokumangalisayo - oluzogcina izakhiwo zensimbi ziphephile izizukulwane ngezizukulwane.

Isikhathi sokuthunyelwe: Meyi-21-2025