I-Hot-DipUkuhlanganisa nge-galvanizing(HDG) inikeza inani eliphakeme kakhulu lesikhathi eside lamaphrojekthi ensimbi. Isibopho sayo esiyingqayizivele sensimbi sinikeza ukuqina okungenakuqhathaniswa ngokumelene nomonakalo. Inqubo yokucwilisa iqinisekisa ukumbozwa okuphelele, okufanayo okungenakuphindaphindwa yizindlela zokufutha. Lokhu kuvikelwa okubili kunciphisa kakhulu izindleko zokulungisa umjikelezo wokuphila.

Imakethe yomhlaba wonke yokukhulisa amandla kulindeleke ukuthi ifinyelele ku-$68.89 billion ngo-2025.umenzi wemishini yokugayayakha okuthuthukileimigqa yokugayaukuhlangabezana nalesi sidingo esikhulayo.

Izinto Ezibalulekile Okufanele Uzicabangele

- Ukushisa okushisayokwenza insimbi iqine kakhulu. Kwakha isibopho esikhethekile esivikela insimbi kangcono kunopende.

- I-galvanizing imboza zonke izingxenye zensimbi. Lokhu kuvimbela ukugqwala ukuthi kuqale ezindaweni ezifihliwe.

- Insimbi egayiwe iyonga imali ngokuhamba kwesikhathi. Ihlala isikhathi eside futhi idinga ukulungiswa okuncane kunezinye izembozo.

Yini Eyenza I-Hot-Dip Galvanizing Ibe Yisinqumo Esiphezulu?

I-Hot-Dip Galvanizing (HDG) ihlukile kwezinye izindlela zokuvikela ukugqwala. Ukuphakama kwayo kuvela emandleni amathathu ayinhloko: isibopho sensimbi esihlanganisiwe, ukumbozwa okuphelele kokucwiliswa, kanye nesistimu yokuvikela enezenzo ezimbili. Lezi zici zisebenza ndawonye ukuletha ukusebenza okungenakuqhathaniswa kanye nenani lesikhathi eside.

Ukuqina Okungenakuqhathaniswa Ngesibopho Sensimbi

Upende nezinye izembozo zimane zinamathele ebusweni bensimbi. Ukufaka i-hot-dip galvanizing kudala ukuqeda okuba yingxenye yensimbi uqobo. Inqubo ihilela ukucwilisa ingxenye yensimbii-zinc encibilikisiweKushiswe cishe ku-450°C (842°F). Lokhu kushisa okuphezulu kubangela ukusabela kokusabalala, okuhlanganisa i-zinc ne-iron ndawonye.

Le nqubo yakha uchungechunge lwezendlalelo ze-zinc-iron alloy ezihlukile. Lezi zendlalelo ziboshelwe ngensimbi ku-substrate yensimbi.

- Isendlalelo seGamma: Eduze kakhulu nensimbi, cishe ine-zinc engu-75%.

- Isendlalelo se-Delta: Isendlalelo esilandelayo siphuma, cishe sine-zinc engu-90%.

- Isendlalelo se-Zeta: Ingqimba ebanzi equkethe cishe i-zinc engu-94%.

- Isendlalelo se-Eta: Ingqimba yangaphandle ye-zinc emsulwa enikeza isembozo isiphetho sayo sokuqala esikhanyayo.

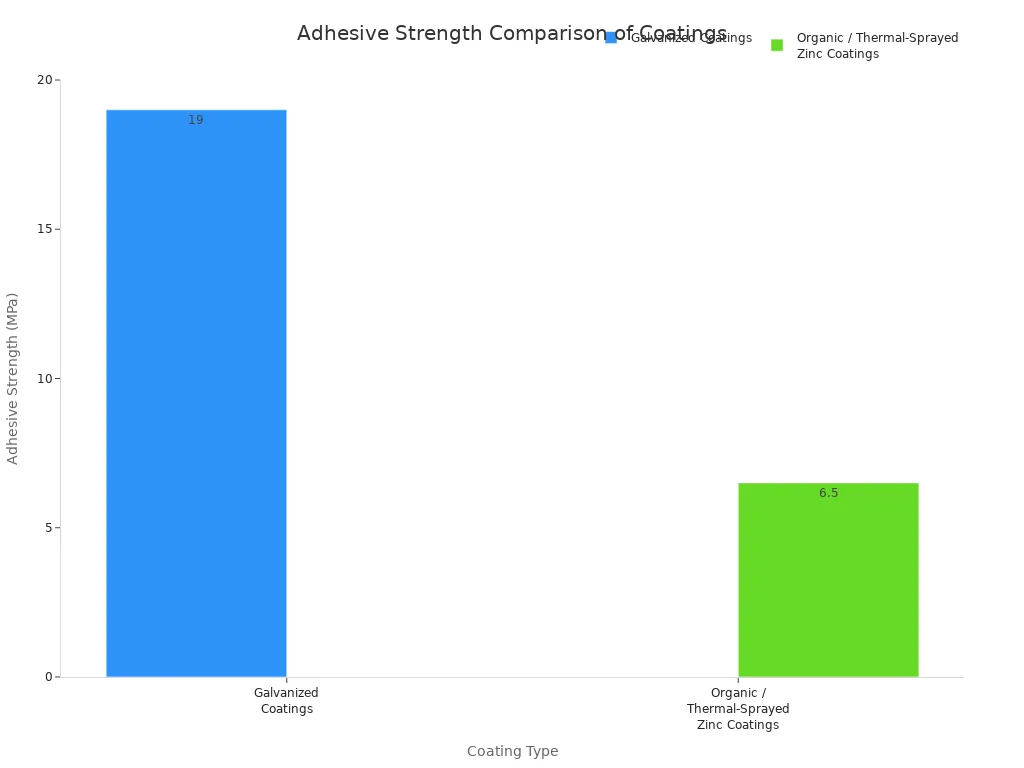

Lezi zendlalelo ezixhumene empeleni ziqinile kunensimbi eyisisekelo, zinikeza ukumelana okungavamile nokuklwebheka kanye nomonakalo. Izendlalelo zangaphakathi eziqinile ziyamelana nokuklwebheka, kuyilapho ungqimba lwangaphandle lwe-zinc oluhlanzekile kakhulu lungamunca imivimbo. Lesi sibopho sensimbi siqine kakhulu kunezibopho zemishini zezinye izembozo.

| Uhlobo Lokumboza | Amandla e-Bond (psi) |

|---|---|

| I-Hot-Dip egayiwe | ~3,600 |

| Ezinye Izimbozo | 300-600 |

Lokhu kuqina okukhulu kwesibopho kusho ukuthi uqweqwe oluhlanganisiwe kunzima kakhulu ukulukhipha noma ukuluqhekeza. Lumelana ngokwethembeka nobunzima bokuthutha, ukuphatha, kanye nokwakhiwa endaweni.

Ukumbozwa Okuphelele Kokuvikelwa Okuphelele

Ukugqwala kuthola indawo ebuthaka kakhulu. Upende ofuthwayo, i-primer

s, kanye nezinye izembozo zisengozini yamaphutha okusetshenziswa njengamaconsi, ukugijima, noma izindawo ezingafakwanga. Lokhu kungapheleli okuncane kuba izindawo zokuqala zokugqwala.

Ukufaka i-hot-dip galvanizing kususa le ngozi ngokucwiliswa ngokuphelele. Ukucwilisa yonke into eyenziwe ngensimbi ku-zinc encibilikisiwe kuqinisekisa ukumbozwa okuphelele. I-zinc ewuketshezi igeleza kuyo yonke indawo, phezu kwayo, naseduze kwayo.

Yonke ikona, unqenqema, umthungo, kanye nengxenye engaphakathi engenalutho ithola ungqimba olufanayo lwesivikelo. Lokhu kuhlanganiswa "konqenqema kuya konqenqema" kuqinisekisa ukuthi azikho izindawo ezingavikelekile ezishiywe zichayeke emvelweni.

Lokhu kuvikelwa okuphelele akuyona nje indlela engcono kakhulu; kuyisidingo. Izindinganiso zomhlaba wonke ziphoqelela leli zinga lekhwalithi ukuqinisekisa ukusebenza kahle.

- I-ASTM A123kudinga ukuthi isiphetho se-galvanized siqhubeke, sibushelelezi, futhi sifane, singabi nezindawo ezingamboziwe.

- I-ASTM A153ibeka imithetho efanayo yehadiwe, ifuna ukuqeda okuphelele nokunamathelayo.

- I-ISO 1461kuyindinganiso yamazwe ngamazwe eqinisekisa ukuthi izinto ezenziwe ngensimbi zithola ukumbozwa okugcwele, okufanayo.

Le nqubo iqinisekisa isithiyo esivikelayo esihlala njalo kuso sonke isakhiwo, into engeke ikwazi ukuphinda isetshenziswe ngokufutha ngesandla noma ngebhulashi.

Isenzo Esiphindwe Kabili: Isivikelo Nokuzidela

Ukwembozwa nge-galvanized kuvikela insimbi ngezindlela ezimbili ezinamandla.

Okokuqala, isebenza njenge-isembozo sesithiyo. Izingqimba ze-zinc zivala insimbi ukuthi ingathintani nomswakama nomoya-mpilo. I-Zinc ngokwayo iyakwazi ukumelana kakhulu. Ezindaweni eziningi zomoya, i-zinc igqwala ngesivinini esisheshayo izikhathi eziyi-10 kuya kwezingama-30 kunensimbi. Leli zinga lokugqwala elihamba kancane linikeza isivikelo esibonakalayo esihlala isikhathi eside.

Okwesibili, inikezaisivikelo somhlatshelo. I-Zinc isebenza kakhulu ngamakhemikhali kagesi kunensimbi. Uma ungqimba lonakaliswe ukuklwebheka okujulile noma umgodi wokubhoboza, i-zinc izoqala ngokugqwala, "izidele" ukuze ivikele insimbi eveziwe. Lokhu kuvikelwa kwe-cathodic kuvimbela ukugqwala ekungeneni ngaphansi kongqimba futhi kungavikela izindawo ezingenalutho ezifika ku-¼ intshi ububanzi. I-zinc empeleni isebenza njengomqaphi wensimbi, iqinisekisa ukuthi noma ngabe umkhawulo uphukile, isakhiwo sihlala siphephile ekugqwaleni. Le mpahla yokuziphilisa iyinzuzo eyingqayizivele yeukugaya nge-galvanizing.

Inqubo ye-HDG: Uphawu Lwekhwalithi

Ikhwalithi evelele yengubo ehlanganisiwe efakwe i-hot-dip ayiyona ingozi. Ivela enkambisweni eqondile, enezigaba eziningi eqinisekisa ukuqeda okuhle kakhulu. Le nqubo iqala isikhathi eside ngaphambi kokuba insimbi ithinte i-zinc encibilikisiwe.

Kusukela Ekulungiseleleni Okungaphezulu Kuya Ekucwilisweni Kwe-Zinc Encibilikisiwe

Ukulungiswa kahle kwendawo kuyisici esibaluleke kakhulu ukuze kube nokugqoka okuphumelelayo. Insimbi kumele ihlanzeke ngokuphelele ukuze kwenzeke ukusabela kwensimbi. Le nqubo ihilela izinyathelo ezintathu ezibalulekile:

- Ukususa amafutha: Isixazululo esishisayo se-alkali sisusa ukungcola okungokwemvelo njengokungcola, amafutha, namafutha ensimbi.

- Ukukhahlela: Insimbi ifakwe ebhavini le-asidi encibilikisiwe ukuze kususwe isikali sokugaya kanye nokugqwala.

- Ukufudumeza: Ukucwilisa kokugcina esixazululweni se-zinc ammonium chloride kususa noma yimaphi ama-oxide okugcina bese kufakwa ungqimba oluvikelayo ukuvimbela ukugqwala okusha ukuthi kungakheki ngaphambi kokugaya.

Ngemva kwalokhu kuhlanzwa okuqinile kuphela lapho insimbi ifakwa khona ebhavini le-zinc elincibilikisiwe, elivame ukushiswa lifinyelele cishe ku-450°C (842°F).

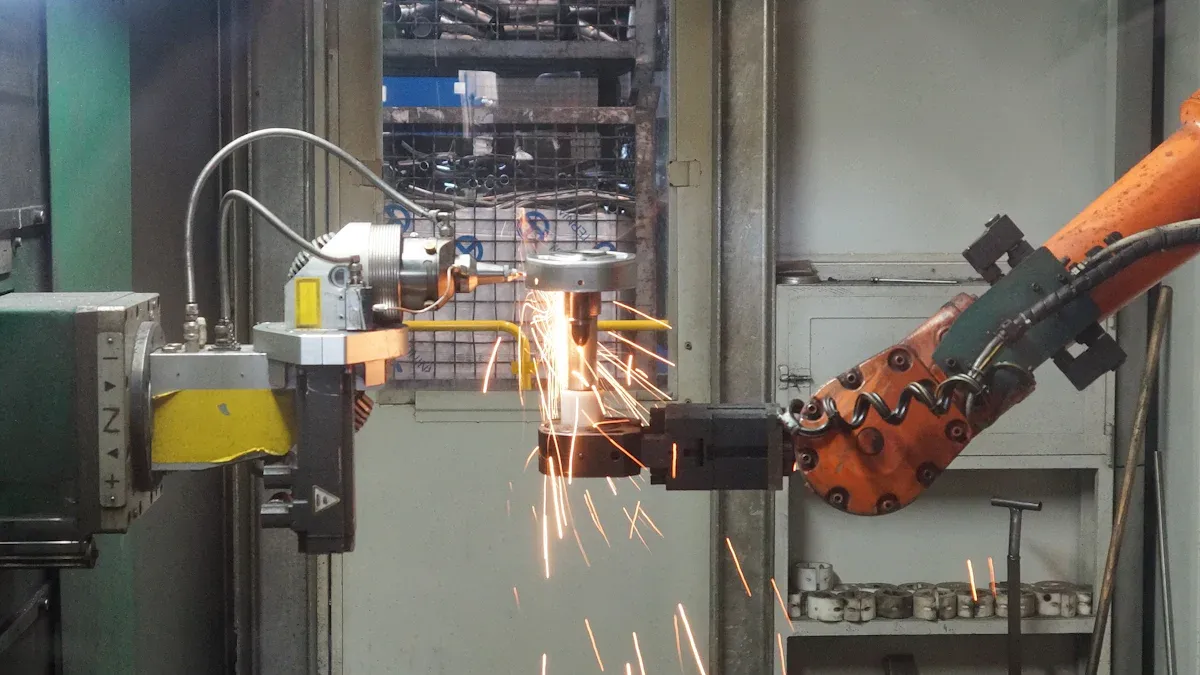

Indima Yomkhiqizi Wemishini Yokubumba I-Galvanizing

Ikhwalithi yenqubo yonke incike emishinini. Umkhiqizi wemishini yokugaya uchwepheshe uklama futhi akhe imigqa ethuthukisiwe eyenza i-HDG yesimanje ibe nokwenzeka. Namuhla, umkhiqizi wemishini yokugaya uhola phambili uhlanganisa izinzwa ezenzakalelayo kanye nezesikhathi sangempela ukuze kulawulwe ngokunembile. Lokhu kuqinisekisa ukuthi isinyathelo ngasinye, kusukela ekuhlanzweni kwamakhemikhali kuya ekuphathweni kokushisa, silungiswa. Ngaphezu kwalokho, unjiniyela wemishini yokugaya ubophekile onjiniyela bezinhlelo ezihlangabezana nezindinganiso eziqinile zemvelo nezokuphepha, ezivame ukufaka izinhlelo ezivaliwe zokuphatha imfucuza. Ubuchwepheshe bomkhiqizi wemishini yokugaya bubalulekile emiphumeleni ehambisanayo nekhwalithi ephezulu.

Indlela Ubukhulu Bokumboza Okuqinisekisa Ngayo Isikhathi Eside

Inqubo elawulwayo, ephethwe izinhlelo ezivela kumkhiqizi wemishini ye-galvanizing ephezulu, ithinta ngqo ukujiya kokugcina kokumboza. Lokhu kujiya kuyisibonakaliso esibalulekile sempilo yenkonzo yensimbi. Ukumboza okujiyile nokufana kakhulu kwe-zinc kunikeza isikhathi eside sokuvikela kokubili isithiyo kanye nokuvikela okuzidelayo. Izindinganiso zemboni zichaza ukujiya okuncane kokumboza ngokusekelwe ohlotsheni kanye nosayizi wensimbi, okuqinisekisa ukuthi ingakwazi ukumelana nendawo ehlosiwe amashumi eminyaka ngokunakekelwa okuncane.

I-HDG vs. Ezinye Izindlela: Ukuqhathaniswa Kokusebenza Kwango-2025

Ukukhetha uhlelo lokuvikela ukugqwala kudinga ukubhekisisa ukusebenza, ukuqina, kanye nezindleko zesikhathi eside. Nakuba kunezinye izindlela eziningi,ukucwilisa okushisayoifakazela njalo ukuthi ingcono kakhulu uma iqhathaniswa ngqo nopende, ama-epoxies, nama-primer.

Ukulwa Nopende kanye Nezimbozo Ze-Epoxy

Upende kanye ne-epoxy coating kungama-surface films. Akha ungqimba oluvikelayo kodwa awahlangani ngamakhemikhali nensimbi. Lo mehluko oyisisekelo uholela ezikhaleni ezinkulu zokusebenza.

Izembozo ze-epoxy zivame ukwehluleka kakhulu. Zingaqhekeka futhi ziqhekeke, ziveze insimbi engaphansi. Uma isithiyo sesiphukile, ukugqwala kungasakazeka ngokushesha. I-New York State Thruway Authority yafunda lokhu mathupha. Ekuqaleni basebenzisa i-rebar ene-epoxy-coated ukulungisa imigwaqo, kodwa izembozo zaqhekeka ngokushesha. Lokhu kwaholela ekuwohlokeni okusheshayo kwemigwaqo. Ngemva kokushintshela ku-rebar ene-galvanized ukuze kulungiswe ibhuloho, imiphumela yayimangalisa kangangokuthi manje basebenzisa izinto ze-galvanized kumaphrojekthi abo.

Ukulinganiselwa kwezembozo ze-epoxy kuyacaca uma kuqhathaniswa ne-HDG.

| Isici | Izembozo ze-Epoxy | Ukushisa Okushisayo |

|---|---|---|

| Ukubopha | Kwakha ifilimu ebusweni; akukho sibopho samakhemikhali. | Kwakha isibopho samakhemikhali nensimbi. |

| Indlela Yokwehluleka | Ithambekele ekuqhekekeni nasekuqhekekeni, okuvumela ukugqwala ukuthi kusabalale. | Izakhiwo zokuzilapha zivikela imihuzuko futhi zivimbele ukugqwala. |

| Ukuqina | Ingaqhekeka kalula ngesikhathi sokuthutha nokufakwa. | Izendlalelo ze-alloy eziqinile kakhulu ziyamelana nokuguguleka kanye nokushayeka. |

| Ukulungisa | Akukho ikhono lokuzilungisa. Izindawo ezonakele kumele zilungiswe ngesandla. | Ivikela ngokuzenzakalelayo izindawo ezincane ezonakele ngesenzo sokuzidela. |

Ukusetshenziswa kanye nokugcinwa kwayo nakho kuletha izinselele ezinkulu zokumbozwa kwe-epoxy.

- Ingozi Yomonakalo: I-Epoxy iyaphuka. Ukuklwebheka ngesikhathi sokuthutha noma sokufaka kungadala izindawo ezibuthakathaka zokugqwala.

- Ukuzwela kwe-UVInsimbi embozwe nge-epoxy idinga ama-tarps akhethekile okugcina ngaphandle. Kumelwe ihlale imboziwe ukuze ivimbele umonakalo ovela elangeni.

- Ukulahlekelwa Kokunamathela: Isibopho sesembozo nensimbi singaba buthaka ngokuhamba kwesikhathi, ngisho nalapho sigcinwa khona.

- Izindawo ZasolwandleEzindaweni ezisogwini, izembozo ze-epoxy zingenza kabi kunensimbi engenalutho. Usawoti kanye nomswakama kuxhaphaza kalula noma yikuphi ukushiyeka okuncane kwezembozo.

Ezindaweni ezisogwini, i-HDG ikhombisa ukuqina kwayo. Ngisho nasezindaweni ezinemimoya eqondile enosawoti, insimbi eqinisiwe ingahlala iminyaka emi-5-7 ngaphambi kokudinga ukulungiswa kokuqala. Izindawo ezivikelekile esakhiweni esifanayo zingahlala zivikelwe iminyaka engu-15-25 eyengeziwe.

Ama-Primer Acebile Nge-Zinc

Ama-primer acebile nge-zinc avame ukwethulwa njengendlela ehlukile yoketshezi esikhundleni se-galvanizing. Lawa ma-primer aqukethe iphesenti eliphezulu lothuli lwe-zinc oluxutshwe ku-paint binder. Izinhlayiya ze-zinc zinikeza isivikelo sokuzidela, kodwa uhlelo luthembele ekubopheni okwenziwa ngomshini, njengopende ojwayelekile.

I-hot-dip galvanizing, ngokuphambene nalokho, idala izendlalelo zayo zokuvikela ngokusebenzisa ukusabela kokusabalalisa emazingeni okushisa aphezulu. Lokhu kwakha ama-alloy e-zinc-iron angempela ahlanganiswe nensimbi. I-primer ecebile nge-zinc imane inamathele ebusweni. Lo mehluko ekuhlanganiseni uyisihluthulelo sokusebenza okuphezulu kwe-HDG.

Isici Ukushisa Okushisayo I-Primer Ecebile Nge-Zinc Indlela yokusebenza Isibopho sensimbi sakha izendlalelo ze-zinc-iron alloy eziqinile. Uthuli lwezinki olusesikhwameni sokubopha lunikeza isivikelo sokuzidela. Ukunamathela Ihlanganiswe nensimbi enamandla ebhondi angu-~3,600 psi. Ukubopha kwemishini kuncike ekuhlanzekeni kwendawo; kubuthakathaka kakhulu. Ukuqina Izendlalelo ze-alloy eziqinile kakhulu ziyamelana nokuguguleka kanye nokushayeka. Upende othambile ofana nopende ungaklwejwa noma uqhekezwe kalula. Ukufaneleka Ilungele insimbi yokwakha ezindaweni ezinzima nezihlala isikhathi eside. Kungcono kakhulu uma kwenziwa izinto zokulungisa noma uma i-HDG ingenzeki. Nakuba ama-primer acebile nge-zinc anikeza isivikelo esihle, awakwazi ukulingana nokuqina kanye nobude bengubo yangempela ehlanganisiwe. Ukusebenza kahle kwe-primer kuncike ngokuphelele ekulungiseleleni nasekusetshenzisweni okuphelele kwendawo, futhi ihlala isengozini yokuklwebheka kanye nokulimala ngokomzimba.

Ukubhekana Nokugxekwa Okuvamile Kwe-HDG

Umbono ovamile ongalungile mayelana nokufaka i-hot-dip galvanizing yizindleko zayo zokuqala. Esikhathini esidlule, i-HDG ngezinye izikhathi yayibhekwa njengenketho ebiza kakhulu kusengaphambili. Kodwa-ke, lokho akusenjalo ngo-2025.

Ngenxa yamanani e-zinc azinzile kanye nezinqubo ezisebenza kahle kakhulu, i-HDG manje incintisana kakhulu ngezindleko zokuqala. Uma ucabangela izindleko zomjikelezo wokuphila, i-HDG cishe njalo iyona ndlela engabizi kakhulu. Ezinye izinhlelo zidinga ukulungiswa njalo kanye nokufakwa kabusha, okwengeza izindleko ezinkulu empilweni yephrojekthi.

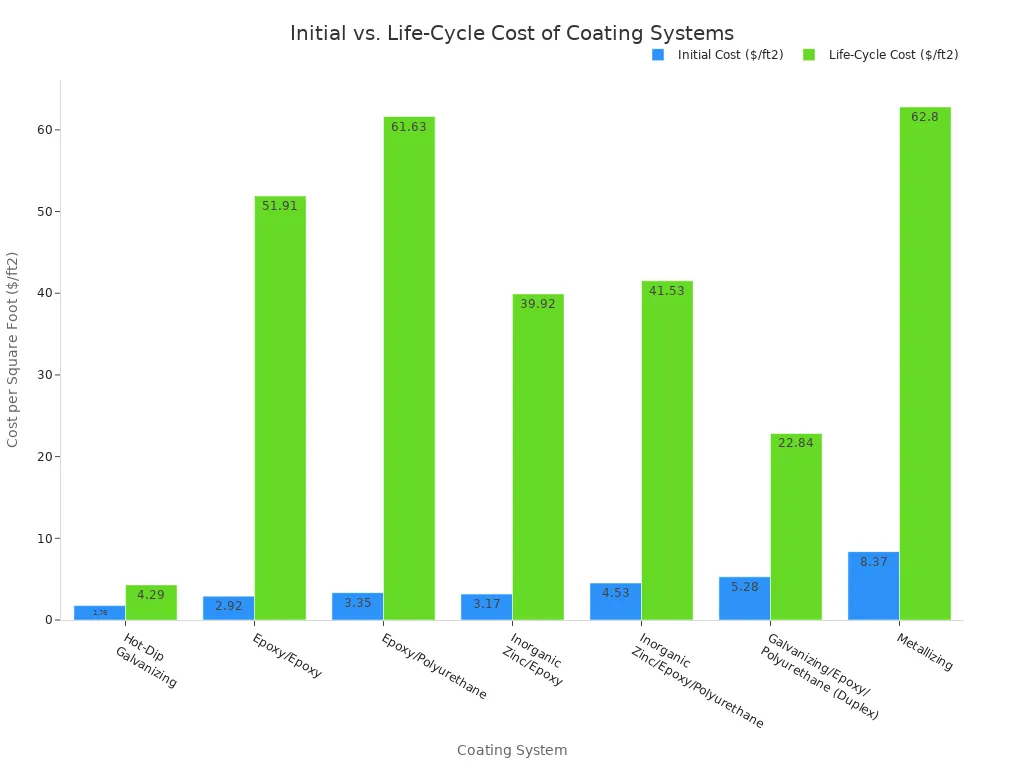

Umthombo Wesithombe:statics.mylandingpages.co I-American Galvanizers Association inikeza i-Life-Cycle Cost Calculator (LCCC) eqhathanisa i-HDG nezinye izinhlelo ezingaphezu kuka-30. Idatha ikhombisa njalo ukuthi i-HDG isindisa imali. Isibonelo, kolunye ucwaningo lwebhuloho elinokuphila komklamo kweminyaka engu-75:

- Ukushisa Okushisayoyayinezindleko zomjikelezo wokuphila$4.29 ngefidi lesikwele.

- I-AnI-Epoxy/i-Polyurethaneuhlelo lwalunezindleko zomjikelezo wokuphila$61.63 ngefidi lesikwele.

Lo mehluko omkhulu uvela ekusebenzeni kwe-HDG okungenakulungiswa. Isakhiwo esenziwe nge-galvanized singahlala iminyaka engama-75 noma ngaphezulu ngaphandle kokudinga umsebenzi omkhulu. Lokhu kwenza kube ukutshalwa kwezimali okuhlakaniphile kakhulu kumaphrojekthi esikhathi eside.

Isikhathi sokuthunyelwe: Okthoba-28-2025