Ukulibaziseka okuqhubekayo kuvame ukuba yinselele ekusebenzeni kwe-galvanizing. Izikhathi zokulinda ama-crane, ukuhlanzwa okungaguquki kwe-izindlu zokugezela ezisebenzisa i-galvanizing, kanye nezingqinamba zenqubo kuyizinkinga ezivamile. Ukuzenzakalela okuqondiwe kuxazulula ngqo lezi zinkinga. Ukusebenzisa izixazululo ezithile ezifana ne-advancedImishini Yokuphatha Izintokuthuthukisa umkhiqizo, kunciphisa izindleko zokusebenza, futhi kuthuthukisa kakhulu ukuphepha kwabasebenzi eduze kwesitshalo.

Izinto Ezibalulekile Okufanele Uzicabangele

- Ukuzenzakalela kulungisa ukubambezeleka okuvamile ku-izitshalo zokugayaKwenza ukusebenza kwe-crane kusheshe futhi kube okunembe kakhudlwana.

- Amathuluzi azenzakalelayo agcina i-zinc bath ihlanzekile. Lokhu kuthuthukisa ikhwalithi yomkhiqizo futhi kwenza inqubo iphephe kakhulu kubasebenzi.

- Izinhlelo ezizenzakalelayo zihambisa izinto kahle phakathi kwezinyathelo. Lokhu kumisa izithiyo futhi kwenza wonke umugqa wokukhiqiza usebenze kangcono.

Ukusebenza Okungafanele Kwe-Crane Nokuphathwa Ngesandla

Inkinga: Ukulibaziseka Kwe-Crane Yesandla kanye Nezingozi Zokuphepha

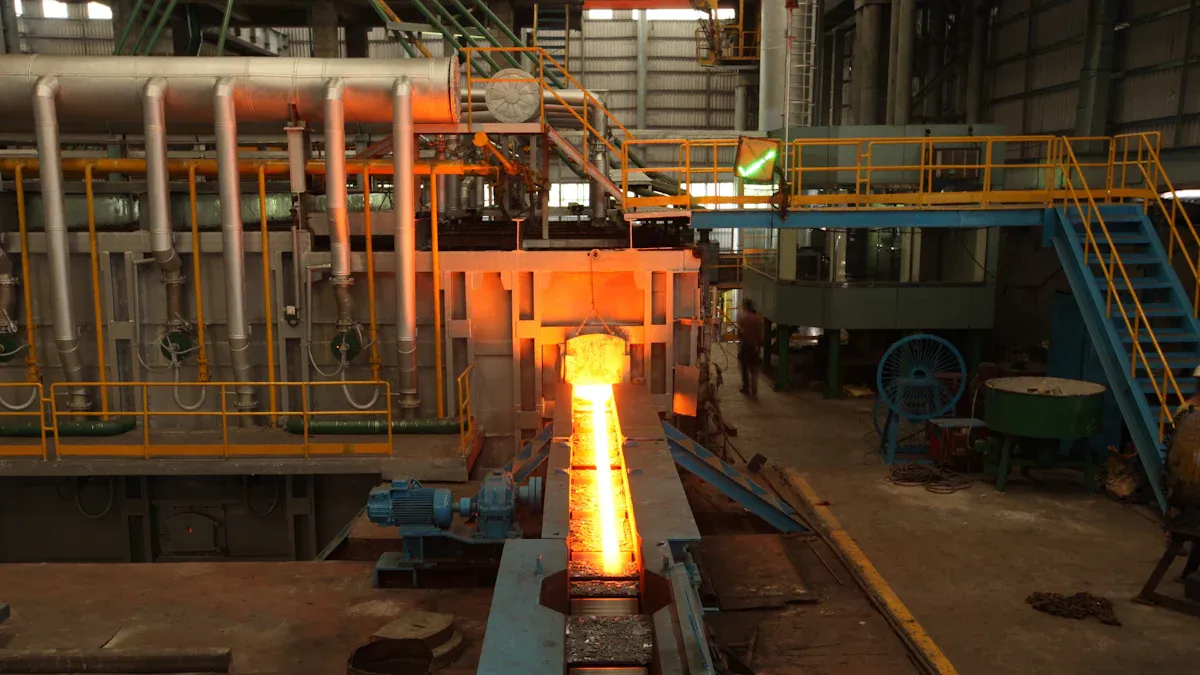

Ama-crane enziwe ngesandla avame ukubambezeleka ekukhiqizweni kwezitshalo ezisebenzisa i-galvanizing. Ukusebenza kuncike ngokuphelele ekutholakaleni kanye nekhono lomuntu osebenzisa i-operator. Lokhu kuthembela kwethula ukuguquguquka kanye nezikhathi zokulinda, njengoba ama-jig nezinto zilandelana ukuze ziphakanyiswe futhi zithuthwe. Izinhlelo ezenziwe ngesandla zinemikhawulo engokwemvelo ngesivinini kanye nokunemba, okuvame ukudala izithiyo ezinkulu zokukhiqiza.

Uthi bewazi?Umzuzu ngamunye umugqa wokukhiqiza olinda i-crane umane nje ulahlekile, okuthinta ngqo inzuzo kanye nezinhlelo zokulethwa.

Lokhu kubambezeleka akuyona nje inkinga yokusebenza kahle; futhi kubeka nezingozi zokuphepha. Ukuphathwa ngesandla kwezinto ezisindayo, ezishisayo, noma eziphathwe ngamakhemikhali kwandisa amathuba ezingozi kanye namaphutha omqhubi. Ukwenza lesi sigaba sibe ngcono kubalulekile ekudaleni umsebenzi ophephile nokhiqizayo, oqala kangcono.Imishini Yokuphatha Izinto.

Isixazululo: I-Automated Crane kanye ne-Hoist Systems

Izinhlelo ze-crane ezizenzakalelayo kanye nezinhlelo zokuphakamisa zinikeza ikhambi eliqondile nelisebenzayo. Lezi zinhlelo zenza imisebenzi yokuphakamisa ephindaphindwayo ngokuzenzakalela, zisheshisa izikhathi zomjikelezo futhi zinciphise isikhathi sokungasebenzi esihambisana nokusebenza ngesandla. Ama-hoist kagesi ahlanganiswe nama-crane aphezulu akha umongo womugqa wokukhiqiza wesimanje, ahambisa izingxenye ngesivinini kanye nokukhuthazela okungenakuqhathaniswa nezinhlelo zezandla. Lokhu kuzenzakalelayo kubalulekile ekuphakamiseni okuphezulu, okuphindaphindayo lapho ukuhambisana kubalulekile khona.

Ama-crane esimanje azenzakalelayo aklanyelwe indawo edinga ugesi. Anikeza ukulawula okunembile nokuhlelekile kuyo yonke intshukumo.

| Ipharamitha | Inani Elijwayelekile |

|---|---|

| Umthamo Wokulayisha | Amathani angu-5 kuya kwangu-16 (okungenziwa ngezifiso) |

| Isivinini Sokuphakamisa Ukuphakamisa | Kufika ku-6 m/min (okuguquguqukayo) |

| Isivinini Sokuhamba Nge-Crane | Kufika ku-40 m/min (okuguquguqukayo) |

| Uhlelo Lokulawula | Isekelwe ku-PLC esebenza kude |

| Izici Zokuphepha | Ukugwema ukushayisana, ukuqapha umthwalo |

Ngokuhlanganisa lobu buchwepheshe, izitshalo zingenza ngcono yonke indlela yokusebenza kwazo. Ama-crane azenzakalelayo asebenza kahle nezinyeImishini Yokuphatha Izintoukuqinisekisa ukushintshana okushelelayo phakathi kwezinqubo. Lokhu kuthuthukiswa kuthuthukisa umkhiqizo, kuthuthukisa ukuphepha ngokususa abasebenzi ezindaweni eziyingozi, futhi kwenza lonke uhla lwemishini yokuphatha izinto lusebenze kahle kakhulu.

Ukuhlanzwa Kwekettle Okungaguquguquki kanye Nokungcoliswa Kwezinki

Inkinga: Ukungasebenzi kahle kokukhipha indle ngesandla kanye nokukhipha indle

Ukulungiswa kwekettle ngesandla kuwumthombo omkhulu wokuguquguquka kwenqubo kanye nokuchitha. Ukulahlwa okungekuhle kuvumela amakhemikhali e-zinc-iron ukuthi angcolise umkhiqizo wokugcina, kulimaze ukuphela kwawo. Ngokufanayo, uma abasebenzi bengasusi kahle ama-zinc skimmings (i-oxidized zinc) ebusweni bebhavu, lawa ma-depositi angahlala ensimbini ngesikhathi sokukhipha. Lokhu kususwa okungekuhle kuvumela ama-oxide ukuthi abambeke ngaphakathi kwe-galvanized coating, okudala ukungalingani okuthinta kabi ikhwalithi yokubonakala komkhiqizo.

Ngaphandle kwekhwalithi yomkhiqizo, ukulahlwa kwempahla ngesandla kulimaza kakhulu abasebenzi. Le nqubo ibabeka ezingozini eziningi zokuphepha.

Izingozi Ezivamile Zokulahla Amanzi Ngesandla

- Ukucindezeleka kwemisipha emhlane ongezansi nasezingalweni ngenxa yokuphakamisa amathuluzi asindayo.

- Amacala aqinisekisiwe e-carpal tunnel syndrome kanye nokulimala kwesandla.

- Ukuchayeka njalo ekushiseni okukhulu okuvela ku-zinc encibilikisiwe.

- Ukuma okungajwayelekile kwehlombe kanye nomzimba okwandisa umthwalo ongokomzimba.

Lokhu kuhlanganiswa kwemiphumela engaguquki kanye nezingozi zokuphepha kwenza ukuhlanza ikettle ngesandla kube yinto eyinhloko yokwenza izinto ngokuzenzakalela.

Isixazululo: Amathuluzi Okugcotshwa Kwerobhothi Nokukhuhla

Amathuluzi okusula nokukhipha amarobhothi anikeza enye indlela enembile nethembekile. Lezi zinhlelo ezizenzakalelayo zisebenza ngokungaguquguquki okungenakuqhathaniswa, zithuthukisa ngqoinqubo yokufaka i-galvanizingUkunyakaza kwabo okulawulwayo kususa ukungcola futhi kususe ubuso bokugeza ngaphandle kokudala ukuxokozela okungadingekile ku-zinc encibilikisiwe. Lokhu kuholela endaweni yekettle ehlanzekile nezinzile.

Izinhlelo ezizenzakalelayo zisebenzisa ubuchwepheshe obuthuthukisiwe njengombono womshini ukuze zibone futhi zisuse i-slag ngempumelelo. Lokhu kuthuthukisa kunciphisa ukusetshenziswa kwe-zinc kanye namandla ngokuqeda imijikelezo yokuhlanza engadingekile. Izinzuzo zicacile:

- Ziqinisekisa ukuthi ukugeza kuhlanzekile, zivimbela “izindawo ezishisayo” ezisendaweni ukuze kucwiliswe ngokulinganayo.

- Basusa ukungcola ngokunyakaza okulawulwayo nokuthambile.

- Zisebenza ngesimiso esifanayo, zigcina ubumsulwa obuhle kakhulu be-zinc.

Ngokwenza lo msebenzi obalulekile ube ngokuzenzakalelayo,izitshalo zokugayaukunciphisa imfucuza ye-zinc, ukuthuthukisa ikhwalithi yokugqoka, nokususa abasebenzi emsebenzini oyingozi.

Ukwenza ngcono ukuhamba komsebenzi ngemishini yokuphatha izinto ezenzakalelayo

Inkinga: Izithiyo Zangaphambi Kokwelashwa Nangemva Kokwelashwa

Ukusebenza kahle komugqa we-galvanizing kuvame ukuwohloka ngesikhathi sokushintsha. Ukunyakaza kwezinto ngesandla phakathi kwamatangi okulungisa ngaphambi kokwelashwa, i-kettle ye-galvanizing, kanye neziteshi zokupholisa ngemuva kokwelashwa kudala izithiyo ezibalulekile. Ama-jig alayishwe ngensimbi kumele alinde i-crane kanye nomsebenzisi otholakalayo, okubangela imigqa kanye nemishini yokungasebenzi. Le nqubo yokuma nokuhamba iphazamisa isigqi sokukhiqiza, inciphisa ukudlula, futhi yenza kube nzima ukugcina isikhathi sokucubungula esihambisanayo somthwalo ngamunye. Ukulibaziseka ngakunye kulezi zindawo zokudlulisa kuhambisana nomugqa wonke, kunciphisa amandla esitshalo kanye nokusebenza kahle.

Isixazululo: Izinhlelo Zokudlulisa Ezizenzakalelayo Ngokugcwele

Izinhlelo zokudlulisa ezizenzakalelayo ngokuphelele zinikeza ikhambi eliqondile kulezi ziphazamiso zomsebenzi. Le Mishini Yokuphatha Izinto Esezingeni Eliphezulu isebenzisa inhlanganisela yamabhande okuhambisa, ama-roller, kanye nezilawuli ezihlakaniphile ukuze zenze ngokuzenzakalelayo futhi zihlele ukuhamba kwezinto. Lezi zinhlelo zenzelwe ukuhlanganiswa okungenamthungo nengqalasizinda yezitshalo ekhona, izigaba zokuxhuma ezifana nezitofu zokushisa, amabhavu okufaka i-galvanizing, kanye nemishini yokupholisa. Ukusetha okuvamile kufaka ibhande lokuhambisa elinezinduku zokubeka izinto ukuze kuvikelwe izinto kanye nebhokisi lokupholisa ukuze kuphole kahle izingxenye zensimbi ngomoya namanzi.

Ngokuzenzakalela yonke inqubo yokudlulisa, lezi zinhlelo ziqeda ukungenelela ngesandla kanye nokubambezeleka okuhambisana nakho. Izinzwa ezihlakaniphile nezinhlelo zokulawula ziqinisekisa ukuqala, ukuma, kanye nokubeka okuzenzakalelayo ukuze kube nokuhamba komsebenzi okubushelelezi nokuqhubekayo. Leli zinga lokulawula lithuthukisa ukuhambisana nokuzinza kwenqubo yonke.

Ukulawulwa Kwenqubo OkuthuthukisiweIzinhlelo zokulawula ezithuthukisiwe njenge-Programmable Logic Controllers (PLCs) kanye nezinhlelo zokukhiqiza (MES) zinikeza ukuqapha okuphelele komugqa. Ziphatha izindlela zokupheka ezisebenzayo futhi zinikeza ukulandeleka okugcwele kusukela ezintweni ezingavuthiwe kuya kumkhiqizo oqediwe.

Lokhu kuhlanganiswa kwezilawuli ezihlakaniphile nemishini yokuphatha izinto eqinile kukhulisa ukusebenza kwenqubo, kuthuthukisa ukusebenza kahle kokukhiqiza, futhi kudala indawo yokusebenza ephephile neqondakala kalula.

Ukuzenzakalela kuqeda ngempumelelo ukubambezeleka okuphindaphindiwe kokuphathwa ngesandla kanye nokuguqulwa kwenqubo. Ama-crane azenzakalelayo namathuluzi erobhothi kuyizixazululo eziqinisekisiwe ezithuthukisa ukuphepha. Ziphinde zithuthukise ukukhiqizwa, ngedatha ebonisa ukuthi ukuzenzakalela kuthuthukisa umkhiqizo ngo-10% ezindaweni eziningi. Ukuhlola izithiyo ezithile zomugqa kukhomba lapho isu eliqondiwe liletha khona inzuzo ephezulu kakhulu.

Isikhathi sokuthunyelwe: Disemba 15-2025