Abaphathi bathola izikhala ezibalulekile zokusebenza, kusukela ekungasebenzeni kahle kwesithando kuya ezinhlelweni zokulawula eziphelelwe yisikhathi.Ifektri Yokukhiqiza Umugqa Wokubumba Nge-Galvanizingibeka phambili ukuthuthukiswa okunenzuzo ephezulu kakhulu, kufaka phakathiIzingxenye Ezincane Imigqa Yokubumba (Robort)Basebenzisa ukwenziwa kwesimanje ngezigaba ezihleliwe ukuze banciphise isikhathi sokungasebenzi.

Okubalulekile Okufanele Ukwenze:Le ndlela yamasu iletha izinzuzo ezibonakalayo. Lokhu kufaka phakathi ikhwalithi yomkhiqizo ethuthukisiwe, izindleko zokusebenza eziphansi, kanye nokwanda kwenzuzo iyonke.

Izinto Ezibalulekile Okufanele Uzicabangele

- Qala ngokuhlola okugcwele umshini wakho ukuze uthole izinkinga bese unquma ukuthi yini okufanele uyilungise kuqala.

- Thuthukisa izinhlelo ezindala ngobuchwepheshe obusha ukuze umshini wakho usebenze kangcono futhi wonge imali.

- Qeqesha ithimba lakho ngamathuluzi amasha futhi uqhubeke uthuthuka ukuqinisekisa ukuthi umshini wakho uhlala usebenza kahle.

Isinyathelo 1: Yenza Ukuhlolwa Okuphelele Komugqa

Ukuthuthukiswa kwesimanje okuphumelelayo kuqala ngokuhlolwa okuphelele. Lesi sinyathelo sokuqala sinikeza umhlahlandlela ocacile wokuthuthukisa. Sikhomba ubuthakathaka obuthile ngaphambi kokuba kwenzeke noma yikuphi ukutshalwa kwezimali. Ukuhlolwa okuningiliziwe kusiza abaphathi ukuqonda isimo sangempela semisebenzi yabo.

Izithiyo Zenqubo Yokukhomba

Abaphathi baqala ngokubona izindawo ezinciphisa ukukhiqizwa noma eziwohloza ikhwalithi. Lezi zingqinamba zivame ukuziveza njengeziphambeko zomkhiqizo eziphindaphindayo. Ukuhlolwa ngokucophelela kungaveza izinkinga eziningi ezivamile. Lezi zinkinga zithinta ngqo inzuzo kanye nokwaneliseka kwamakhasimende.

- Ukufakwa Kwamatshe: Izinhlayiya ezincane ze-zinc-iron alloy zingalimaza ukumelana kokugqwala kwesembozo.

- Izindawo Ezingenalutho: Lezi zindawo ezingamboziwe zivame ukubangelwa ukulungiswa okungekuhle kwendawo noma i-aluminium eningi eketeleni.

- Ukuqhekeka: Ukumbozwa okunzima kungadala ukucindezeleka okukhulu, okubangela ukuthi ungqimba lwezinki luhlukane nensimbi.

- Amaqhubu Nokugijima: Lokhu kwenzeka ngenxa yesivinini sokuhoxa esingalungile noma amazinga okushisa okugeza angafanele.

- Ukugoba: Ama-patches ampunga angakheka ngenxa yokuqukethwe okuphezulu kwe-silicon noma i-phosphorus ensimbini.

Hlola Impilo Yesistimu

Okulandelayo, amaqembu kumele ahlole isimo semishini eyinhloko. Lokhu kufaka phakathiisithando somlilo, ama-drive, kanye nezinhlelo zokulawula. Uhlelo olugugayo lungase luzabalaze ukugcina isivinini kanye nokushisa okuhambisanayo. Lokhu kuthinta ngqo ukusebenza kwamandla kanye nokusetshenziswa kwamandla. I-Galvanizing Production Line Factory yesimanje kumele ivumelanise amandla ayo nesivinini sayo sokusebenza.

Isivinini somugqa we-galvanizing sivame ukuba phakathi kuka-3-30 m/min. Umthamo wokusebenzisa ugesi uyisihluthulelo sokucabanga ukuze kuqhathaniswe isivinini somugqa nomthamo wokukhiqiza.

Hlaziya Idatha Yokusebenza

Idatha inikeza ukuqonda okuqondile ngokusebenza kahle komugqa. Abaphathi kufanele baqoqe futhi bahlaziye izinkomba zokusebenza ezibalulekile (ama-KPI). Lolu lwazi luqokomisa izitayela futhi luqinisekisa umthelela wezithiyo. Ukulandelela lezi zilinganiso kubalulekile ekulinganiseni impumelelo yokuthuthukiswa kwesikhathi esizayo. Amaphuzu edatha abalulekile afaka:

- Umkhiqizo wokukhiqiza

- Ukusetshenziswa kwemishini

- Izindleko zokulungisa

Isinyathelo 2: Beka phambili ukuthuthukiswa kobuchwepheshe okubalulekile

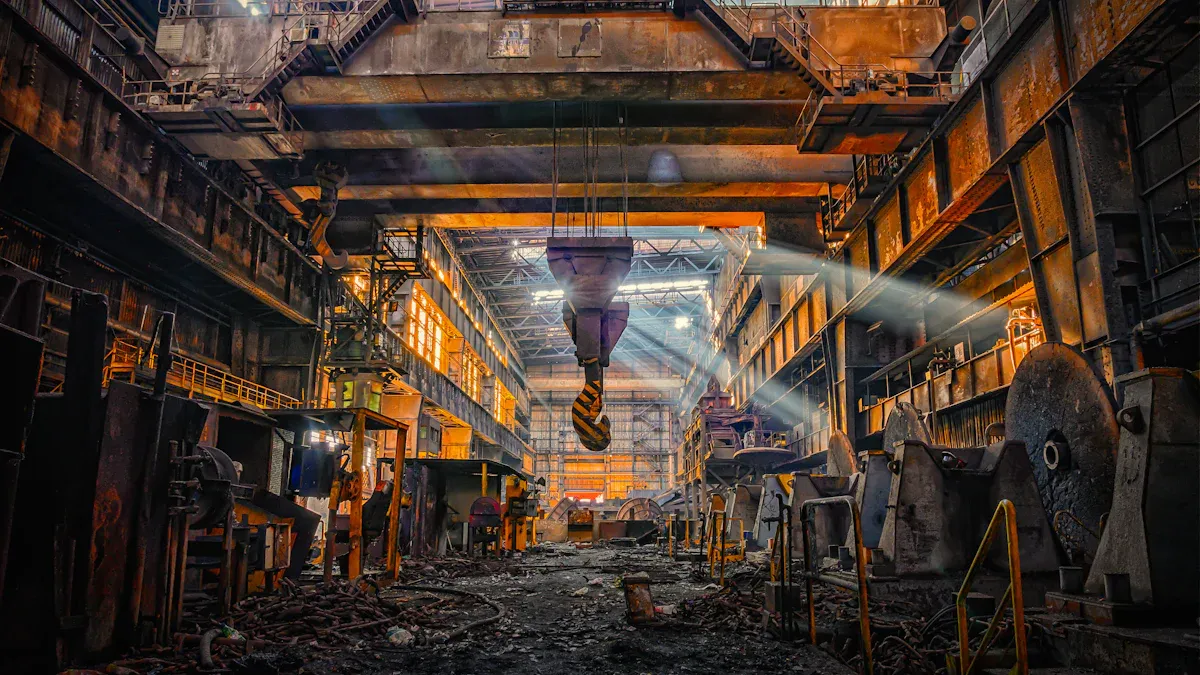

Umthombo Wesithombe:susa i-splash

Ngemva kokuhlolwa okuphelele, abaphathi bangakhomba ukuthi yikuphi ukuthuthukiswa kobuchwepheshe okuzoletha imbuyiselo ephezulu kakhulu ekutshalweni kwezimali. Ukugxila ekulawulweni kwenqubo, izinhlelo zemishini, kanye nokulawulwa kwekhwalithi kudala isisekelo esinamandla sokusebenza kwesimanje, okusebenzayo, nokunenzuzo.

Yenza kube sesimanje ukulawulwa kwenqubo kanye nokuzenzakalela

Izinhlelo zokulawula eziphelelwe yisikhathi ziwumthombo oyinhloko wokungasebenzi kahle.Ukuzenzakalela kwesimanjekwenza kube lula ukukhiqizwa, kunciphisa isikhathi sokungasebenzi, futhi kuvumela ukushintsha okusheshayo phakathi kwamazinga ahlukene ensimbi. Ukuthuthukela ohlelweni oluzenzakalelayo lwezinga 2 kunikeza ubuchopho obuphakathi kulo lonke ulayini. Izici ezibalulekile zifaka:

- Uhlelo lwekhompyutha lokulawula inqubo ngesikhathi sangempela.

- Ukufuduka kwekhodi endala (njenge-FORTRAN) kuya ezilimini zesimanje ezifana ne-C#.

- Ukuthuthukiswa kwezixhumi zomsebenzisi ezinembile (ama-UI).

- Ukushintsha kusuka kwisitoreji sedatha esisekelwe kumafayela kuya kudathabheyisi ye-Oracle eqinile.

Ama-Modern Programmable Logic Controllers (PLCs) kanye nama-Human-Machine Interfaces (HMIs) anika amandla opharetha ukwenza izinqumo ezihlakaniphile nezisheshayo. Lezi zinhlelo zinikeza ukusebenza okubonakalayo ngokugcwele ngamadeshibhodi wesikhathi sangempela. Opharetha bangaqapha izinkomba zokusebenza ezibalulekile (ama-KPI) njenge-Overall Equipment Effectiveness (OEE) kanye ne-throughput ukuze bathole izitayela nokuthuthukisa ukusebenza kahle.

I-HMI enembile isebenza njengebhuloho phakathi komqhubi nomshini. Iguqula idatha eluhlaza evela kuzinzwa namanethiwekhi okulawula ibe ukuqonda okusebenzayo, inciphisa izikhathi zokuphendula zokuxilonga nama-alamu.

Lokhu kuhlanganiswa kwenza kube lula ukugcinwa kwemishini ngokushesha. I-PLC ingalandelela amakhulu amaphuzu edatha, njengokudlidliza kwemoto kanye nokushisa kwamabhere, futhi ixwayise amaqembu ngezinkinga ezingaba khona ngaphambi kokuba kwenzeke ukwehluleka. Lokhu kuvumela ukugcinwa kwemishini ukuthi kuhlelwe ngesikhathi sokuvalwa okuhleliwe esikhundleni sokusabela ekuqhekekeni okubizayo. Imbuyiselo yalezi zimali ivame ukuba ngokushesha futhi ibalulekile.

| Inkampani | Uhlelo Luqalisiwe | Ukunciphisa Izindleko Zokusebenza | Ukwanda Komkhiqizo |

| I-SteelTech Inc. | Ukulandelela okuzenzakalelayo kwempahla, ukulungiswa kokubikezela | 15% | 20% |

| Umkhiqizi Wensimbi | Uhlelo lokuphatha amandla oluzenzakalelayo | 3% ngonyaka | Ukwenyuka kwentengo ephansi okungu-1.35% |

Thuthukisa Amadrayivu Nezinhlelo Zemishini

Imishini ebonakalayo yomugqa ibaluleke kakhulu njengohlelo lwayo lokulawula.izingxenye zemishinikuyizinto ezivame ukwehluleka, okuholela ekungasebenzeni kahle kwesikhathi kanye nekhwalithi yomkhiqizo engaguquki.

Ukuthuthukiswa okuyinhloko ukushintsha kusuka kuma-DC drive amadala kuya kuma-AC vector drive esimanje. Ama-AC drive anikeza ukusebenza okuphezulu kanye nezindleko eziphansi zokuphila konke. Agcina amandla e-factor amahle kakhulu kuzo zonke izivinini, anciphisa ukusetshenziswa kwamandla kufika ku-15% kwezinye izimo.

| Uhlobo lweDrayivu | Isidingo Sokulungisa | Ukuthembeka |

| Amadrayivu e-AC | Iphansi (akukho mabhulashi noma ama-commutator) | Umklamo ophakeme (wesimo esiqinile) |

| Ama-DC Drives | Okuphezulu (amabhulashi kanye nama-commutator) | Okuphansi (kuncike ekugugeni komshini) |

Ngaphezu kwalokho, ama-motor e-AC afaneleka kangcono endaweni enothuli yomshini wokugaya i-galvanizing. Ukwakheka kwawo okupholile ngaphandle kuvimbela ukungcola, ngokungafani nama-motor e-DC apholile ngaphakathi adinga umoya ohlungiwe. Ubuchwepheshe obufana ne-Direct Torque Control (DTC) bunikeza ama-AC drive isivinini esiqondile kanye nokulawula i-torque, ngokuvamile kususa isidingo samadivayisi okuphendula angaphandle.

Ukwehluleka kwemishini, ikakhulukazi ukuphuka kwamalunga okushibilika, kungamisa umugqa kuze kube amahora angu-48. Lokhu kwehluleka kuvame ukubangelwa yimingcele yokushibilika engafanele noma ukukhathala kwezinto ezibonakalayo. Ukuze balwe nalokhu, abaphathi kufanele batshale imali ezingxenyeni eziqinile zemishini. Ukuthuthukisa ama-pot roll bearings kuyintuthuko enomthelela omkhulu.

| Uhlobo Lokuthuthukisa | Izinto/Ukucushwa | Ukuthuthukiswa Kokusebenza |

| Izinto Zokuthwala | Izimbozo ze-Al2O3 (Alumina) | Ukumelana nokugqwala okuphezulu kakhulu emabhavini e-Zn-Al kanye ne-Zn-Al-Mg. |

| Ukucushwa Kwebhereyi | Ukubhanqa i-SS 316L embozwe nge-Al2O3 kanye ne-Wallex6TM | Ukucushwa okungenzeka kokuqina nokusebenza okuthuthukisiwe. |

Hlanganisa Ukulawulwa Kwekhwalithi Okuthuthukisiwe

I-Galvanizing Production Line Factory yesimanje isusa ukulawulwa kwekhwalithi kusuka esinyathelweni sokugcina sokuhlola iye enqubweni ehlanganisiwe, yesikhathi sangempela. Lokhu kushintsha kunciphisa udoti, konga izinto zokusetshenziswa, futhi kuqinisekisa ukuthi yonke imikhiqizo ihlangabezana nezindinganiso eziqinile.

Ukuhlolwa kobuso okuzenzakalelayo kuyisisekelo sokulawulwa kwekhwalithi yesimanje. Lezi zinhlelo zisebenzisa amakhamera okubona asebenzisa i-AI kanye ne-high resolution ukuthola amaphutha ngesikhathi sangempela ngesivinini esifinyelela kumamitha ayi-1,200 ngomzuzu. Zingahlonza:

- Ukugqoka kwe-zinc okungalingani

- Amabala okugqwala kanye nokubola

- Ama-voids kanye nemigodi

- Imivimbo kanye nemihuzuko engaphezulu

Okunye ukuthuthukiswa okubalulekile ukuhlanganiswa kwezikali zesisindo sokumboza ngesikhathi sangempela. Lezi zinzwa ezingabhubhisi ziqapha njalo ukumboza kwe-zinc ngesikhathi sokukhiqiza. Lokhu kuvumela ukulungiswa okusheshayo, okuzenzakalelayo kwemimese yomoya, ukuqinisekisa ukumboza okufanayo okuhlangabezana nezimfuneko ngaphandle kokumboza ngokweqile okubizayo. Umphumela uba ukonga okukhulu kwe-zinc, ukuqina komkhiqizo okuthuthukisiwe, kanye nesivuno esiphezulu semishini yokugaya.

Lobu buchwepheshe busiza izikhungo ukuthi zihlangabezane nezindinganiso ezibalulekile zemboni zekhwalithi nokubukeka.

Izindinganiso ezibalulekile zifaka phakathiI-ASTM A123/A123Myemikhiqizo yensimbi nensimbi kanyeI-ISO 1461kwezingxenye ezenziwe. Ukunamathela kulezi zindlela kuqinisekisa ukwamukelwa kwemakethe yomhlaba wonke.

Ngokuhlanganisa lezi zinhlelo ezithuthukisiwe, abaphathi baguqula ukulawulwa kwekhwalithi kusuka esikhungweni sezindleko kube umshayeli wenani, okuthuthukisa idumela lomkhiqizo kanye nokwaneliseka kwamakhasimende.

Isinyathelo 3: Hlela futhi usebenzise iphrojekthi yokuthuthukisa

Ukuthuthukiswa okuphumelelayo kuncike ekuhleleni nasekusetshenzisweni ngokucophelela. Lesi sinyathelo siguqula ukuhlolwa kwezimali kanye nezinto eziza kuqala kwezobuchwepheshe zibe uhlelo oluqondile lwesenzo, sinciphise ukuphazamiseka futhi sandise imbuyiselo ekutshalweni kwezimali.

Thuthukisa Uhlelo Lokusebenza Ngezigaba

Abaphathi kufanele bagweme ukuvalwa ngokuphelele ngokuphula iphrojekthi ibe yizigaba ezilawulekayo.ukuthuthukiswa okugcwelekungathatha iminyaka; isibonelo, isitshalo esisodwa salungisa kabusha imishini yaso esikhathini seminyaka emihlanu. Le ndlela ivumela umsebenzi ukuthi wenzeke ngesikhathi sokuphumula okufushane nokuhleliwe kokukhiqiza. Uhlelo olucacile luhilela izinyathelo eziningana:

- Hlakaza iphrojekthi ibe yizingxenye ezincane, njengamamojula noma izici.

- Hlola ubunzima bengxenye ngayinye (isib., encane, ephakathi nendawo, enkulu).

- Beka phambili izingxenye ngokusekelwe enanini lebhizinisi kanye nengozi.

- Hlanganisa izingxenye zibe yizigaba ezinengqondo ukuze ulinganisele umthwalo womsebenzi.

- Hlela isigaba ngasinye ngezikhathi ezicacile kanye nezigaba ezibalulekile.

Phatha Izingozi Nezimo Ezingalindelekile Zephrojekthi

Yonke iphrojekthi inezinkinga ezingaba khona. Ukuphathwa kwezingozi okusebenzayo kuvikela isikhathi kanye nesabelomali. Abaphathi kufanele bahlonze izehlakalo ezingaba khona zesikhathi sokungasebenzi futhi bakhe izinqubo zokuphendula eziningiliziwe. Ukusebenzisa idatha evela ezinhlelweni zokulungisa ezibikezelayo kusiza ukwenza lezi zinhlelo zesimo esiphuthumayo zibe nembaba kakhulu.

| Ingozi Engaba Khona | Isu Lokunciphisa Ubunzima |

| Isikhathi Sokuphumula Esingalindelekile | Dala ithimba elizinikele lokuphendula elinezindima ezicacile. |

| Ukulibaziseka Kwe-Supply Chain | Gcina uhlu lwezingxenye ezibalulekile ezisele. |

| Izinkinga Zemishini | Yakha izinhlelo eziqinile zezinkinga ezingalindelekile. |

Sebenzisa Ukuhlolwa Kwangaphambi Kokwenziwa kanye Nokungaxhunyiwe Ku-inthanethi

Ukuze kuncishiswe isikhathi sokufakwa endaweni, amaqembu angakha izingxenye endaweni elawulwayo yasefektri. Ukwakha izinto kusengaphambili njengezintambo zokuxhuma kanye nezindawo zokulawula kuvumela ukuhamba komsebenzi okufanayo, njengoba umsebenzi wesisekelo endaweni ungenzeka ngesikhathi esifanayo. Leli cebo linciphisa imfucuza yokwakha futhi lifinyeze isikhathi sephrojekthi iyonke.

Ngaphambi kokuba noma yiluphi uhlelo olusha luqale ukusebenza, kumele luhlolwe ngaphandle kwe-inthanethi. Ukuhlolwa Kokwamukelwa Kwemboni (i-FAT) kuqinisekisa ukuthi uhlelo lusebenza njengoba luklanyelwe. Le nqubo ibamba iningi lezinkinga ngaphambi kokuba imishini ifike ensimini, okusindisa isikhathi nemali ebalulekile ngesikhathi sokusebenza. ✅

Isinyathelo 4: Lungiselela Ifektri Yakho Yokukhiqiza Umugqa We-Galvanizing Wesimanje

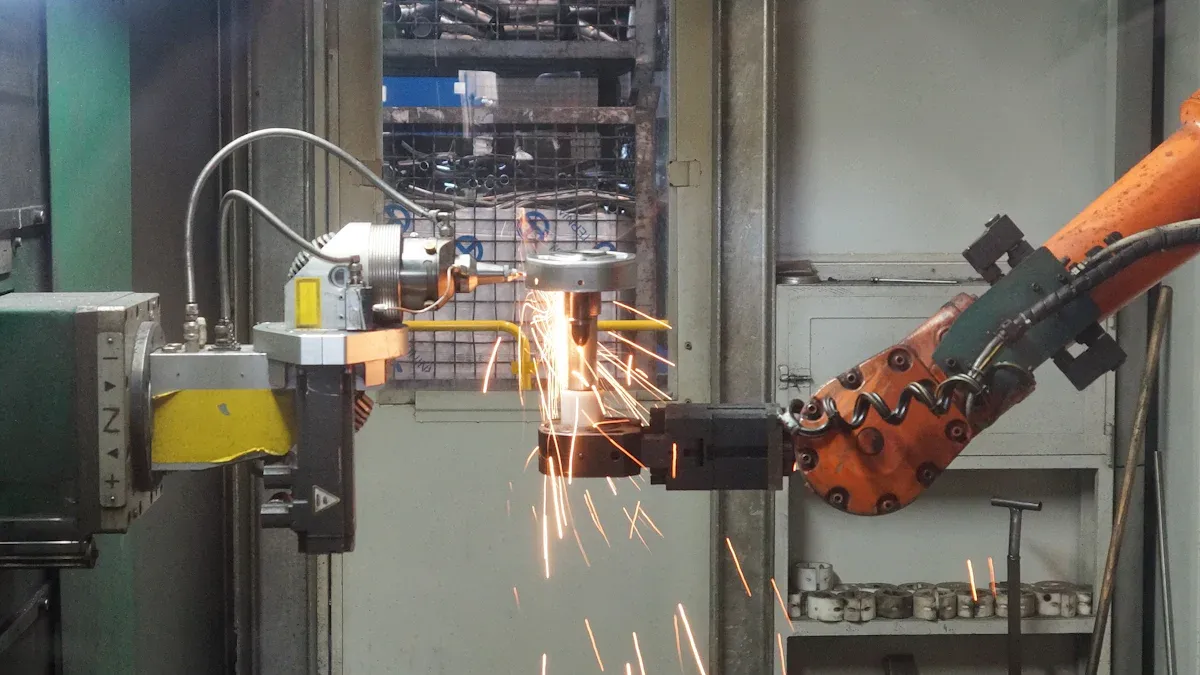

Umthombo Wesithombe:susa i-splash

Ukuthuthukiswa kwesimanje akupheli ngokufakwa. Isinyathelo sokugcina ukwenza ngcono isici somuntu. Lokhu kuqinisekisa ukuthi ubuchwepheshe obusha buletha amandla aso aphelele. Ukuqeqeshwa okufanele, izinqubo ezibuyekeziwe, kanye nesiko lokucabanga kusengaphambili kubalulekile empumelelweni yesikhathi eside.

Qeqesha Abasebenzi Ngezinhlelo Ezintsha

Ubuchwepheshe obusha budinga amakhono amasha. Abaphathi kumele banikeze ukuqeqeshwa okuphelele kubo bonke abasebenzi. Lokhu kulungiselela amaqembu ukusebenzisa okushaizinhlelo zokwenza izinto ngokuzenzakalelangempumelelo. Ukuqeqeshwa okuphumelelayo kuhlanganisa imfundo yobuchwepheshe nama-workshops asebenzayo kanye nokulingisa. Le ndlela yakha ukuzethemba kwabaqhubi endaweni ephephile nelawulwayo. Abasebenzi bokulungisa abaqeqeshwe kahle banikeza izinzuzo ezibalulekile:

- Ukuhlonza inkinga ngokushesha

- Ukunciphisa isikhathi sokuphumula esingahleliwe

- Ukuphila isikhathi eside kwemishini okuthuthukisiwe

- Ukuqina kokusebenza okuthuthukisiwe

Ukuqeqeshwa okuqhubekayo kubalulekile. Kusiza amaqembu ukuthi ahambisane nentuthuko yezobuchwepheshe esheshayo. Lokhu kuzibophezela kuqinisekisa ukuthiIfektri Yokukhiqiza Umugqa Wokubumba Nge-Galvanizingihlala isebenza kahle futhi inokuncintisana.

Buyekeza Izinqubo Zokusebenza Ezijwayelekile

Imishini yesimanje yenza izinqubo ezindala ziphelelwe yisikhathi. Amaqembu kumele abuyekeze Izinqubo Ezijwayelekile Zokusebenza (ama-SOP) ukuze zibonise izinqubo ezintsha zokusebenza nokuphepha. Lokhu kuhlanganisa ukubhala phansi ukusetshenziswa kwemishini emisha, izimpendulo eziphuthumayo, kanye nezinhlelo zokulungisa ezivamile. Ukuphepha kuyinto eza kuqala.

| Isibuyekezo Sokuphepha | Kudingeka Isinyathelo |

| Ukuhlolwa Kwangaphambi Kokusebenza | Hlola nsuku zonke ukuthi awekho yini amaphutha, ukuvuza, noma ukungasebenzi kahle. |

| Izici Zokuphepha | Abaqhubi bezitimela basebenza ngokuvala okuzenzakalelayo kanye nezinzwa. |

| Iziqondiso Zomkhiqizi | Landela ngokuqinile zonke izincwadi zokusebenza nokulungisa. |

| Imishini Yokuzivikela Yomuntu Siqu (i-PPE) | Qinisekisa ukuthi bonke abasebenzi bagqoka izimpahla ezifanele njengezigqoko eziqinile kanye nezibuko zokuphepha. |

Khuthaza Isiko Lokuthuthuka Okuqhubekayo

Umgomo wokugcina isiko lokuthuthuka okuqhubekayo. Ubuholi kumele bukhuthaze lo mqondo. Bangabandakanya abasebenzi kuzo zonke izigaba futhi bakhuthaze imibono yokwenza ngcono okwengeziwe. Ifektri Yokukhiqiza I-Galvanizing yanamuhla iyachuma ngempendulo.

Izisebenzi ze-shift zinolwazi oluqondile ngezithiyo kanye nokungasebenzi kahle. Impendulo yazo inikeza ubuhlakani bokusebenza obuwusizo obungathuthukisa ukuthuthukiswa kwenqubo kanye nokusungula izinto ezintsha.

Abaphathi kufanele basungule izindlela ezicacile zokuphendula. Lokhu kuvumela abasebenzi ukuthi babone izinkinga futhi baphakamise izixazululo. Ukugubha impumelelo kanye nokwenza ngokuvumelana nempendulo kuqinisa isiko lapho ilungu ngalinye leqembu lifaka isandla ekwenzeni ngcono okuqhubekayo. ✅

Ukuthuthukiswa kwesimanje okuphumelelayo kulandela indlela ecacile.

- Kuqala ngokuhlolwa okuphelele ukuze kutholakale ubuthakathaka obuthile.

- Abaphathi bagxila ekutshalweni kwezimali ezindaweni ezine-ROI ephezulu njengokwenza izinto ngokuzenzakalela.

- Uhlelo oluhlelwe ngezigaba lunciphisa isikhathi sokungasebenzi ngesikhathi sokwenziwa.

Umgomo wokugcina ukusebenza okuphumelelayo, okunenzuzo, nokuncintisana kakhudlwana, hhayi imishini emisha kuphela. ✅

Isikhathi sokuthunyelwe: Okthoba-21-2025