Izindleko eziphelele zomtshali-zimali zesitshalo se-hot-dip galvanizing ziwela ezigabeni ezintathu eziyinhloko. Lezi yi-Capital Equipment, i-Infrastructure, kanye ne-Operations.intengo yemishini yokugaya ngogesi eshisayokufaka phakathi izinto ezibalulekile. Lezi zinto ziyi-kettle ye-galvanizing, amathangi okulungisa ngaphambi kokwelashwa, kanye nezinhlelo zokuphatha izinto. Izindleko zengqalasizinda zihlanganisa umhlaba, isakhiwo, kanye nokusetha izinsiza. Izindleko zokusebenza ziyizindleko eziqhubekayo zezinto zokusetshenziswa, amandla, kanye nabasebenzi.

Imakethe yokugaya eshisayo ikhombisa amandla okukhula aqinile. Lokhu kukhula kuqhutshwa ukutshalwa kwezimali kwengqalasizinda kanye nesidingo sezinto ezingagqwali. Imakethe yemikhiqizo efanaimigqa yokugaya amapayipiiyanda.

| I-Metric | Inani |

|---|---|

| Usayizi Wemakethe ngo-2024 | Ama-USD ayizigidigidi ezingama-62.39 |

| Usayizi Wemakethe ngo-2032 | Ama-USD ayizigidigidi ezingama-92.59 |

| I-CAGR (2025-2032) | 6.15% |

Izinto Ezibalulekile Okufanele Uzicabangele

- Ukusetha i-isitshalo sokugayaKubiza imali ngemishini, umhlaba, kanye nezakhiwo. Imishini eyinhloko ihlanganisa iketela lokugaya kanye nemishini yokuhambisa insimbi.

- Ukuqhuba isitshalo sokugaya igesi kunezindleko eziqhubekayo. Lokhu kufaka phakathi ukuthenga i-zinc, ukukhokhela amandla, kanye nokukhokhela abasebenzi.

- Intengo ye-zinc ishintsha njalo. Lolu shintsho luthinta ukuthi kubiza malini ukuqhuba isitshalo nsuku zonke.

Ukutshalwa Kwezimali Kokuqala: Intengo Yemishini Yokugaya Nge-Hot-Dip kanye Nengqalasizinda

Ukutshalwa kwezimali kokuqala kumelela isithiyo sezimali esibaluleke kakhulu lapho kusungulwa isitshalo sokugaya igesi. Lesi sigaba sihlanganisa zonke izindleko zangaphambilini zemishini, izakhiwo zomzimba, kanye nokusetha. Izindleko eziphelele ziyahlukahluka kakhulu ngokusekelwe kumthamo ohlosiwe wesitshalo, izinga lokuzenzakalela, kanye nendawo. Isitshalo esiyisisekelo sezinto ezincane singaqala cishe ku-$20,000. Umugqa wokucubungula omkhulu, oqhubekayo ungadlula u-$5,000,000.

Isampula yokuhlaziywa kokutshalwa kwezimali kwesitshalo esiphakathi nendawo ibonisa ukusatshalaliswa kwezindleko.

| Isigaba | Izindleko (INR Lakh) |

|---|---|

| Umhlaba kanye Nengqalasizinda | 50 – 75 |

| Imishini Nemishini | 120 – 200 |

| Uhlu lweZinc | 15 – 30 |

| Abasebenzi kanye Nezinsizakusebenza | 10 – 15 |

| Ilayisensi Nokuthobela Imithetho | 5 – 10 |

| Ukutshalwa Kwezimali Kokuqala Okuphelele | 200 – 300 |

Ikettle Yokugaya: Usayizi kanye Nezinto Ezisetshenziswayo

Iiketela lokugayaInhliziyo yokusebenza kanye nomshayeli wezindleko oyinhloko. Ubukhulu bayo—ubude, ububanzi, kanye nokujula—bunquma ubukhulu obukhulu bemikhiqizo yensimbi isitshalo esingayicubungula. Ikettle enkulu ibamba i-zinc encibilikisiwe eningi, edinga amandla engeziwe okushisa futhi ikhulisa intengo iyonke yemishini yokugaya eshisayo. Amakettle ngokuvamile enziwa ngensimbi ekhethekile enekhabhoni ephansi, ene-silicon ephansi ukuze imelane nokugqwala okuvela ku-zinc encibilikisiwe. Ikhwalithi yezinto ezibonakalayo ithonya ngqo isikhathi sokuphila kwekettle kanye nemvamisa yokushintshwa kwayo.

Amathangi Angaphambi Kokwelashwa

Ngaphambi kokufaka i-galvanizing, insimbi kumele idlule ochungechungeni lwezinyathelo zokuhlanza. Le nqubo yenzeka emathangini angaphambi kokwelashwa. Inani nosayizi walawa matangi kuncike ekutheni ingakanani i-output efiselekayo kanye nesimo sensimbi engenayo. Umugqa ojwayelekile wangaphambi kokwelashwa uhlanganisa izigaba eziningana:

- Ukususa amafutha:Isusa uwoyela, ukungcola, kanye namafutha.

- Ukuhlanza:Ihlanza amakhemikhali okususa amafutha.

- Ukukha:Isebenzisa i-asidi (njenge-hydrochloric acid) ukususa isikali sokugaya kanye nokugqwala.

- Ukuhlanza:Ihlanza i-asidi.

- Ukushintshashintsha:Faka isixazululo se-zinc ammonium chloride ukuvimbela ukuphinda kufakwe i-oxidation ngaphambi kokucwilisa.

Lawa matanki avame ukwakhiwa ngezinto ezifana ne-polypropylene noma ipulasitiki eqiniswe ngefayibha (i-FRP) ukuze imelane namakhemikhali aqothulayo.

Izinhlelo Zokuphatha Izinto

Ukuphathwa kwezinto ezisetshenziswayo kahle kubalulekile ekukhiqizeni nasekuphepheni. Lezi zinhlelo zithutha insimbi kuzo zonke izigaba zenqubo. Ukukhetha phakathi kwezinhlelo ezenziwe ngesandla, ezizenzakalelayo kancane, kanye nezinhlelo ezizenzakalelayo ngokuphelele kuthinta kakhulu ukutshalwa kwezimali kokuqala.

| Uhlobo Lwesistimu | Ibanga Lentengo Elimaphakathi (i-USD) |

|---|---|

| Umugqa Ozenzakalelayo Kancane | $30,000 – $150,000 |

| Umugqa Ozenzakalelayo Ngokugcwele | $180,000 – $500,000 |

| Isitshalo Sokujika Esingokwezifiso | $500,000+ |

Qaphela:Ukuphathwa ngesandla kunezindleko eziphansi kusengaphambili kodwa kuvame ukuholela ezindlekweni eziphakeme zesikhathi eside. Lezi zindleko zivela ezingozini zasemsebenzini, ukulimala komkhiqizo, kanye nokukhiqizwa okuhamba kancane. Izinhlelo ezizenzakalelayo zidinga ukutshalwa kwezimali kokuqala okukhulu kanye nabasebenzi abanamakhono. Kodwa-ke, ziletha ukusebenza kahle okukhulu ngokuhamba kwesikhathi ngokusebenzisa ukusebenza kahle okukhulu kanye nendawo yokusebenza ephephile. Intengo yemishini ye-hot-dip galvanizing iyanda ngokuzenzakalelayo, kodwa futhi nenzuzo yesikhathi eside yesitshalo iyanda.

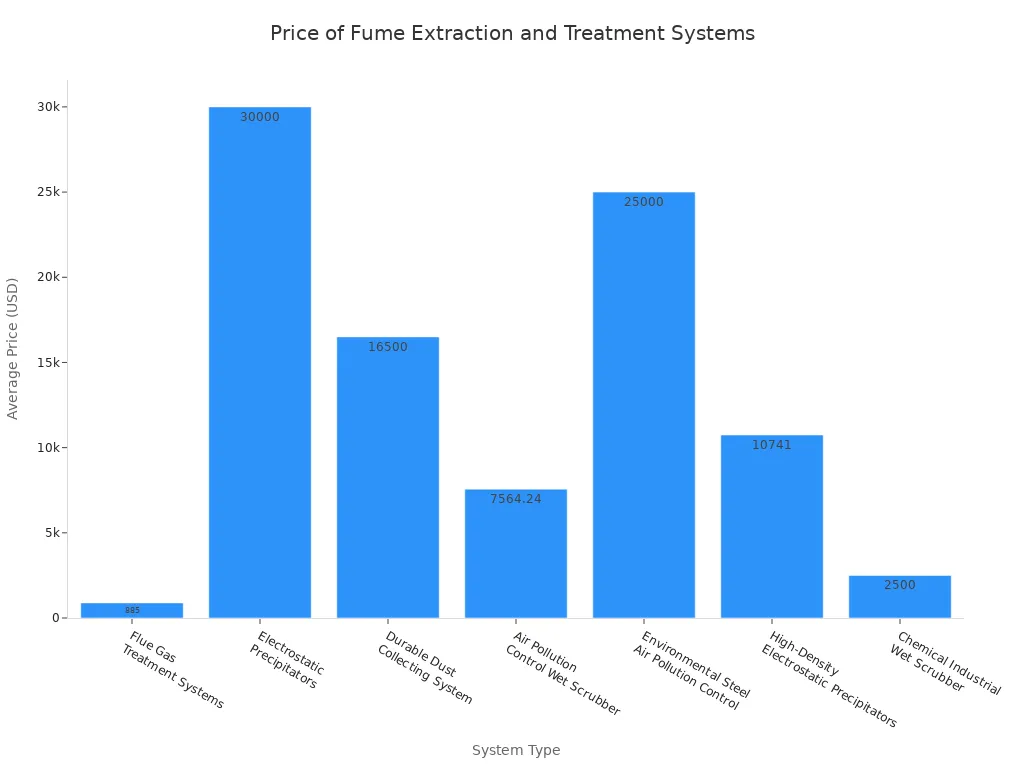

Izinhlelo Zokushisa Nokwelapha Ukushisa

Ikettle yokufaka igesi idinga uhlelo lokushisa olunamandla ukuze igcine i-zinc incibilikile cishe ku-840°F (450°C). Izishisi zegesi yemvelo ezinesivinini esiphezulu ziyisinqumo esivamile. Uhlelo lokuhlanza igesi lubaluleke ngendlela efanayo. Inqubo yokufaka igesi ikhiqiza umusi oyingozi kanye nothuli oludinga ukubanjwa nokwelashwa ukuze kuhlangatshezwane nemithethonqubo yemvelo.

Ukuthobela izindinganiso ezivela kwi-Environmental Protection Agency (EPA) noma kwi-European Union (EU) akunakuxoxiswana ngakho. ENyakatho Melika, ama-70% ezinkampani zokukhiqiza abeka phambili ukuthuthukiswa kwezinhlelo zokuhlunga ukuze kuhlangatshezwane nezindinganiso zekhwalithi yomoya. Amabhizinisi abonisa ukuzimisela ukukhokha iphrimiyamu engu-10-15% yezinhlelo eziqinisekisa ukuthobela imithetho futhi ezinikeza ukuhlunga okuphezulu. Lokhu kwenza uhlelo lokwelapha intuthu lube yingxenye ebalulekile yesabelomali.

Umhlaba kanye neZakhiwo

Izindleko zomhlaba kanye nokwakhiwa kuncike kakhulu endaweni yesitshalo. Isitshalo sokugaya sidinga indawo ebalulekile ukuze sihambisane nomugqa wokukhiqiza wonke, kusukela ekufikeni kwensimbi kuya ekugcineni umkhiqizo oqediwe. Isakhiwo ngokwaso sinezidingo ezithile zomklamo. Kumelwe sibe nophahla oluphezulu ukuze sisebenzise ama-crane aphezulu kanye nezisekelo eziqinile ukuze sisekele imishini esindayo njenge-kettle. Ingqalasizinda efanele yokungenisa umoya nayo ibalulekile ekuphatheni ukushisa kanye nekhwalithi yomoya kulo lonke isikhungo. Lezi zici zenza umhlaba ohlukaniswe ngezimboni kanye nokwakhiwa okukhethekile kube yingxenye enkulu yezindleko zokuqala zemali.

Izinsiza kanye nokufakwa

Isitshalo sokugaya igesi siwumthengi omkhulu wamandla, ikakhulukazi igesi yemvelo kanye nogesi. Ukusetha ukuxhumeka kwezinsizakusebenza ezinamandla aphezulu kuyindleko enkulu kanye kuphela. Izindleko zokufakwa komugqa wegesi yemvelo ziyahlukahluka ngokusekelwe ezicini eziningana:

- Ibanga ukusuka endaweni eyinhloko yokunikezwa kwegesi

- Ubunzima bokugoqa nokufaka imisele

- Uhlobo lwezinto zombhobho ezisetshenzisiwe (isb., insimbi, i-HDPE)

Izindleko zokufaka umugqa omusha wephethiloli zingasukela ku-$16 kuya ku-$33 ngonyawo olulodwa. Umugqa omusha osuka emgwaqweni uya esikhungweni ungadlula kalula u-$2,600, kanti amaphrojekthi ezimboni ayinkimbinkimbi abiza kakhulu. Ngokufanayo, ukusungula uxhumano lukagesi olunamandla aphezulu lwezinjini, ama-crane, kanye nezilawuli kudinga ukubambisana nabahlinzeki bezinsiza zasendaweni futhi kungaba inqubo eyinkimbinkimbi nebiza kakhulu. Ukufakwa kwayo yonke imishini kuyingxenye yokugcina efaka isandla entengweni iyonke yemishini ye-hot-dip galvanizing.

Izindleko Zokusebenza Eziqhubekayo

Ngemva kokusetha kokuqala, i-isitshalo sokugayaImpilo yezezimali yenkampani incike ekuphatheni izindleko zayo zokusebenza eziqhubekayo. Lezi zindleko eziphindaphindayo zithinta ngqo intengo yomkhiqizo wokugcina oqinisiwe kanye nenzuzo iyonke yesitshalo. Ukuphathwa ngokucophelela kwezinto zokusetshenziswa, amandla, abasebenzi kanye nokugcinwa kubalulekile empumelelweni yesikhathi eside.

Izinto Zokusetshenziswa: I-Zinc kanye Namakhemikhali

Izinto zokusetshenziswa zimelela ingxenye enkulu yesabelomali sokusebenza kwesitshalo. I-Zinc iyisici esibaluleke kakhulu nesibiza kakhulu. Intengo ye-Special High Grade (SHG) zinc iyashintshashintsha ngokusekelwe ekuhlinzekweni nasekudingweni komhlaba wonke, okwenza kube yizindleko eziguquguqukayo abaphathi bezitshalo okumele baziqaphe eduze. Izinkomba zemakethe, njenge-'Zinc special high grade in-warehouse Rotterdam premium' enikezwa yi-Argus Metals, inikeza isilinganiso samanani.

Izindleko ze-zinc zingahluka kakhulu phakathi kwabaphakeli nezifunda.

| Incazelo Yomkhiqizo | Ubumsulwa | Ububanzi Bentengo (i-USD/ithani) |

|---|---|---|

| Ingot ekhethekile ye-Zinc High Grade | 99.995% | $2,900 – $3,000 |

| Ingot yeZinc yebanga eliphezulu | 99.99% | $2,300 – $2,800 |

| Ingot ejwayelekile yeZinc | 99.5% | $1,600 – $2,100 |

Qaphela:Amanani angenhla ayabonisa futhi ayashintshashintsha nsuku zonke. Umnikazi wesitshalo kumele asungule iziteshi zokuhlinzeka ezithembekile ukuze aqinisekise amanani ancintisanayo.

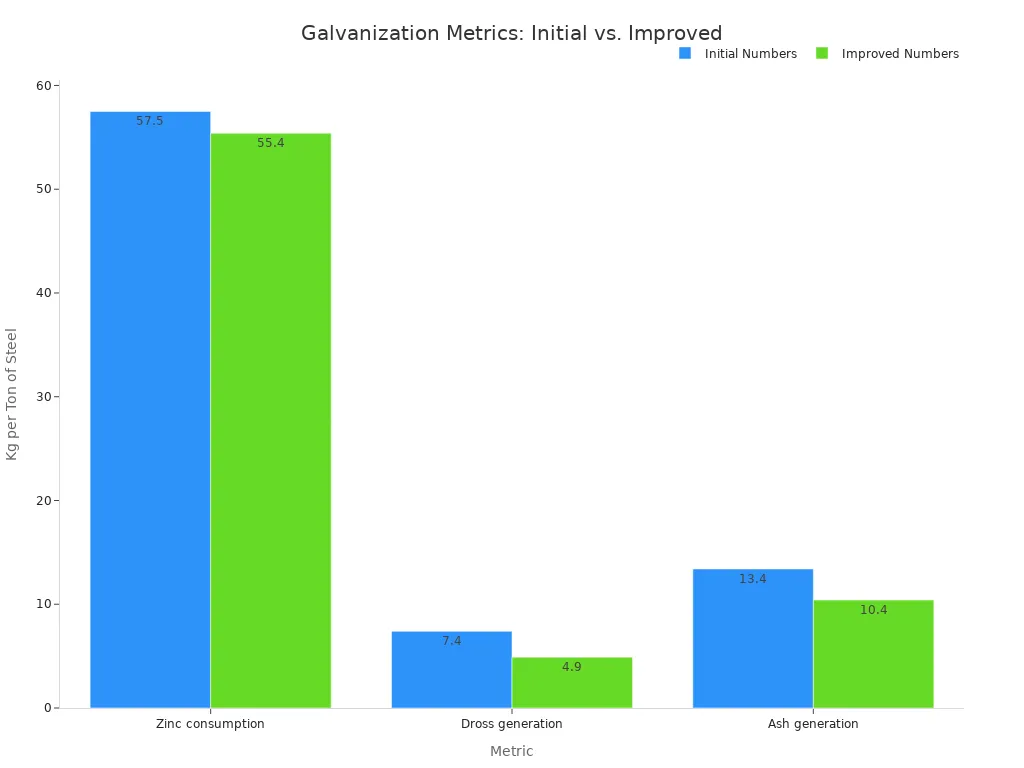

Ukusetshenziswa kwe-zinc esitshalweni kuhlanganisa okungaphezu nje kokumbozwa kwensimbi. Le nqubo idala nemikhiqizo elandelanayo efana ne-zinc dross (i-iron-zinc alloy) kanye nomlotha we-zinc (i-zinc oxide). Le mikhiqizo elandelanayo imelela ukulahleka kwe-zinc esebenzisekayo. Kodwa-ke, ukuthuthukiswa kwenqubo kunganciphisa kakhulu lokhu kungcola. Ukusebenza kahle kuholela ekusetshenzisweni okuphansi kanye nokukhiqizwa okuncane kwemikhiqizo elandelanayo, kunciphisa ngqo izindleko zezinto.

Ezinye izinto zokusetshenziswa ezibalulekile zifaka amakhemikhali enqubo yangaphambi kokwelashwa. Lezi yizi:

- Ama-ejenti okususa amafuthaukuhlanza insimbi.

- I-Hydrochloric noma i-sulfuric acidukuze kukhiqizwe.

- I-zinc ammonium chloridengesisombululo se-flux.

Izindleko zala makhemikhali, kanye nokugcinwa kwawo okuphephile kanye nokulahlwa kwawo, zenezela ezindlekweni zokusebenza eziphelele.

Ukusetshenziswa Kwamandla

Izitshalo zokugaya ugesi ziyimisebenzi edinga amandla amaningi. Izindleko ezimbili eziyinhloko zamandla yigesi yemvelo kanye nogesi.

- Igesi Yemvelo:Uhlelo lwesithando lusebenzisa inani elikhulu legesi yemvelo ukuze lugcine amakhulu amathani e-zinc encibilikisiwe ku-840°F (450°C) ubusuku nemini.

- Ugesi:Ama-motor anamandla aphezulu anika amandla ama-crane aphezulu, amaphampu, kanye nabalandeli bokukhipha intuthu.

Ukutshala imali kubuchwepheshe obusebenzisa amandla kahle kunganciphisa kakhulu lezi zindleko. Imiklamo yesimanje yesithando somlilo, isibonelo, inganciphisa izidingo zamandla zonyaka ngaphezu kuka-20%. Uhlelo oluthuthukisiwe lungase lunciphise ukusetshenziswa kwamandla kusukela399.3 MJ/tonneyensimbi ukuze nje307 MJ/tonneLokhu kwehla okungu-23% kokusetshenziswa kusho ngqo ukonga okukhulu kwezezimali kanye nokuncipha kwekhabhoni, okwenza ukusetshenziswa kwamandla kube umgomo oyinhloko wanoma yisiphi isitshalo sesimanje.

Umsebenzi Nokuqeqeshwa

Abasebenzi abanamakhono nabasebenza kahle bayinjini yesitshalo esifaka ugesi. Izindleko zabasebenzi ziyizindleko ezinkulu zokusebenza futhi ziyahlukahluka ngokuya ngendawo kanye nemithetho yeholo yendawo. Izindima ezibalulekile esitshalweni zifaka:

- Abaqhubi be-crane

- Abasebenzi be-jigging (ukulenga) kanye ne-de-jigging steel

- Abasebenzi bekettle noma “abadiphi”

- Ama-Fettler (okuqeda)

- Abahloli bokulawula ikhwalithi

- Ochwepheshe bokulungisa

Ukuqeqeshwa okufanele akuyona imali eningi kodwa kuyindlela yokutshala imali. Ithimba eliqeqeshwe kahle lisebenza ngokuphepha nangendlela ephumelelayo. Lokhu kunciphisa izingozi emsebenzini, kunciphisa umonakalo emikhiqizweni yamakhasimende, futhi kuqinisekisa ikhwalithi eqhubekayo. Izinhlelo zokuqeqesha eziqhubekayo zisiza abasebenzi ukuthi bahlale benolwazi ngemikhuba emihle yokuphepha, ukuthobela imvelo, kanye nokusebenza kahle, ekugcineni kukhulisa umkhiqizo kanye nedumela lesitshalo.

Ukugcinwa kanye nezingxenye ezisele

Imishini esebenza endaweni enokushisa okuphezulu neqinile idinga ukunakwa njalo. Uhlelo lokulungisa olusebenzayo lubalulekile ukuze kuvinjelwe ukuphazamiseka okungalindelekile kanye nokumiswa kokukhiqiza okubizayo.

Icebiso Lochwepheshe:Uhlelo lokulungisa oluhleliwe lubiza kancane kunokulungisa okuphuthumayo. Ukuhlela ukuhlolwa okuvamile kwe-ikettle, amakhreyini, kanye nohlelo lomusi kuqinisekisa ukuthembeka futhi kwandisa isikhathi sokuphila kwemishini ebizayo.

Imisebenzi ebalulekile yokulungisa ihlanganisa ukugcinwa kwesithando somlilo, ukuhlolwa kwe-crane, kanye nokuhlanza uhlelo lokuhlanza intuthu. Isitshalo kumele futhi sibe nesabelomali sezingxenye ezibalulekile ezisele. Izingxenye ezisele ezivamile zifaka:

- Izitofu kanye nama-thermocouple esithando somlilo

- Izivalo zephampu kanye nama-impeller

- Izihlungi zesistimu yokukhipha intuthu

- Izingxenye zikagesi ezifana nama-contactor nama-relay

Ukuba nalezi zingxenye esandleni kuvumela ukulungiswa okusheshayo, kunciphisa isikhathi sokungasebenzi kanye nokugcina umugqa wokukhiqiza uhamba.

Usayizi wekettle, ingqalasizinda, kanye namanani e-zinc yizona zinto ezibangela izindleko ezinkulu. Amandla esitshalo, ukuzenzekela, kanye nendawo kunquma ukutshalwa kwezimali kokugcina. Intengo yemishini ye-hot-dip galvanizing iyahlukahluka kakhulu. Abatshalizimali kufanele bacabangele isikhathi sokukhokha ngesikhathi sokuhlela.

- Isikhathi sokukhokha esilindelwe esitshalweni esisha kufanele sibe yiminyaka emi-5 noma ngaphansi.

Icebiso:Ukuze uthole isilinganiso esinembile, xhumana nabakhiqizi bezitshalo ukuze uthole isilinganiso esiningiliziwe nesilungiselelwe wena.

Isikhathi sokuthunyelwe: Disemba-02-2025