iyunithi yokuvuselela nokuvuselela kabusha ye-flux

Incazelo Yomkhiqizo

Ukubuyiselwa nokusetshenziswa kokushisa okulahliwe kubhekisela enkambisweni yokubuyisa nokusebenzisa amandla okushisa aqukethwe yigesi (njengegesi yokushisa ephezulu), uketshezi (njengamanzi okupholisa) kanye nezinto eziqinile (njengensimbi ehlukahlukene eshisayo ephezulu) ezinokushisa okuphezulu okuphuma ngesikhathi sokukhiqizwa kwezimboni.

Izinga lokushisa legesi yomoya oshisayo wesithando sokushisa esishisayo licishe libe ngu-400 ℃, futhi inani elikhulu lokushisa okulahliwe kwegesi yomoya oshisayo lingaphinde lisetshenziswe. Abakhiqizi abaningi bakhipha lokhu kushisa ngqo, okubangela ukumosha amandla. Uma kuhlanganiswa nobuchwepheshe bephampu yokushisa, le ngxenye yokushisa ingaphinde isetshenziswe ukuze kudalwe inani elingabizi efektri.

Imininingwane Yomkhiqizo

- Ngokuvamile, ingasetshenziswa ekwenzeni amanzi ashisayo, ekufudumaleni kwenqubo, ekupholiseni nasekuwomiseni. Iqembu lekhompyutha lingahlelwa kuphela ngemva kokuqonda ukushisa okulahliwe nokuvuselela ukushisa kwenqubo entsha. Lapho ukushisa okulahliwe kungahlangabezana nesidingo samandla okushisa senqubo entsha, idivayisi yokutakula ukushisa okulahliwe ingasetshenziswa ngqo ekushintsheni ukushisa. Lapho ukushisa okulahliwe kungakwazi ukuhlangabezana nesidingo samandla okushisa senqubo entsha, ukushisa okulahliwe kungasetshenziswa ekufudumaleni kwangaphambili, futhi ukushisa okunganele kungangezelelwa ngemishini yepompo yokushisa, noma imishini yokufudumeza ekhona.

Kunoma yikuphi, umphumela wokonga amandla usobala kakhulu kunokushisa okulahliwe kokuqala, ukuze kufezwe injongo yokunciphisa ukusetshenziswa kwamandla nokuthuthukisa ukusebenza kahle.

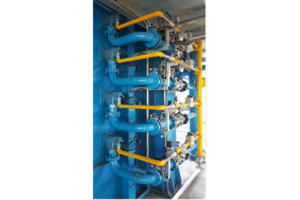

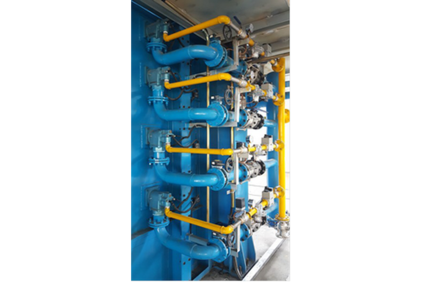

Ngemva kokubuyiselwa kokushisa okulahliwe kusuka ekushiseni kwegesi yomoya womoya womugqa we-galvanizing, ingasetshenziswa ekufuneni kwamanzi ashisayo kanye nokushisa izixazululo ezahlukahlukene ezinqubweni zangaphambi kokwelashwa kanye nangemuva kokwelashwa kwe-hot galvanizing. I-heat exchanger yokubuyisa ukushisa okulahliwe eyenziwe ngokwezifiso inokusebenza kahle kokushintshanisa ukushisa okuphezulu, ukulawula ukusebenza kwesikrini sokuthinta, futhi ingaxhunywa kukhompyutha noma kufoni ephathekayo ukuze kube lula ukuphatha, okusindisa amabhizinisi amashumi ezinkulungwane kuya kwamakhulu ezinkulungwane minyaka yonke.

Ukubuyiselwa kokushisa okulahliwe kuncike kumshini wokushintshanisa ukushisa, kodwa ukwakheka kohlelo kubaluleke kakhulu. Isethi yonke yephrojekthi yokubuyiselwa kokushisa okulahliwe ingaqedwa kuphela uma uhlobo, izinga lokushisa, kanye nokushisa kokushisa okulahliwe kwebhizinisi kulungiselelwe kahle kusenesikhathi, futhi izimo zokukhiqiza, ukugeleza kwenqubo, isidingo samandla sangaphakathi nangaphandle, njll. kuphenywa.

Bhala umlayezo wakho lapha bese uwuthumela kithi